面向多功能工程应用的力学功能超材料的研究进展

通信作者:

焦鹏程,研究员,博士,研究方向为力学功能超材料、监测感知与能量采集、软体机器人。

中图分类号:

V250.2

文献标识码:

A

引文格式:

毛振军, 许海波, 滕园, 等. 面向多功能工程应用的力学功能超材料的研究进展[J]. 航空制造技术, 2025, 68(15): 47–62.

摘要

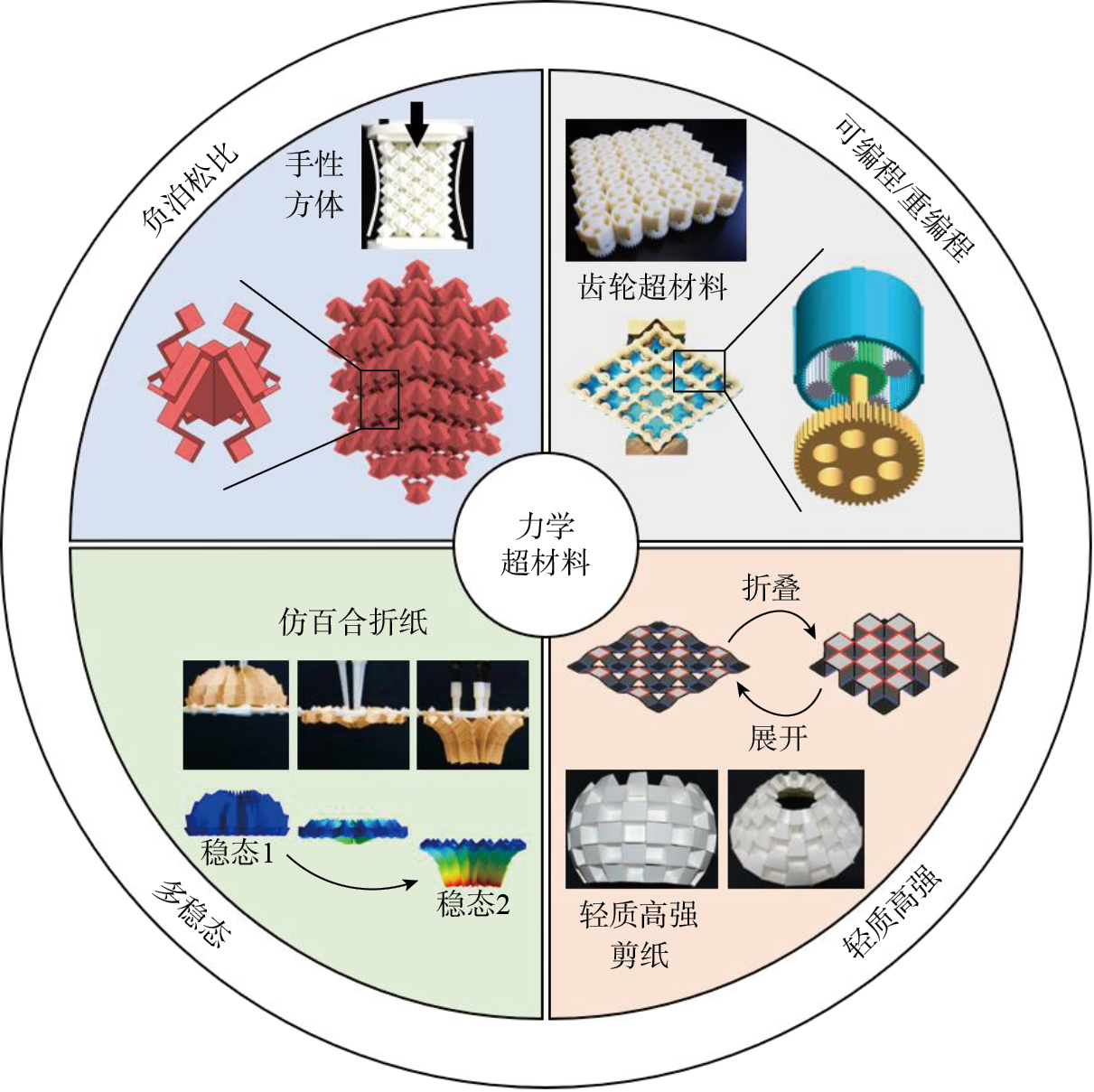

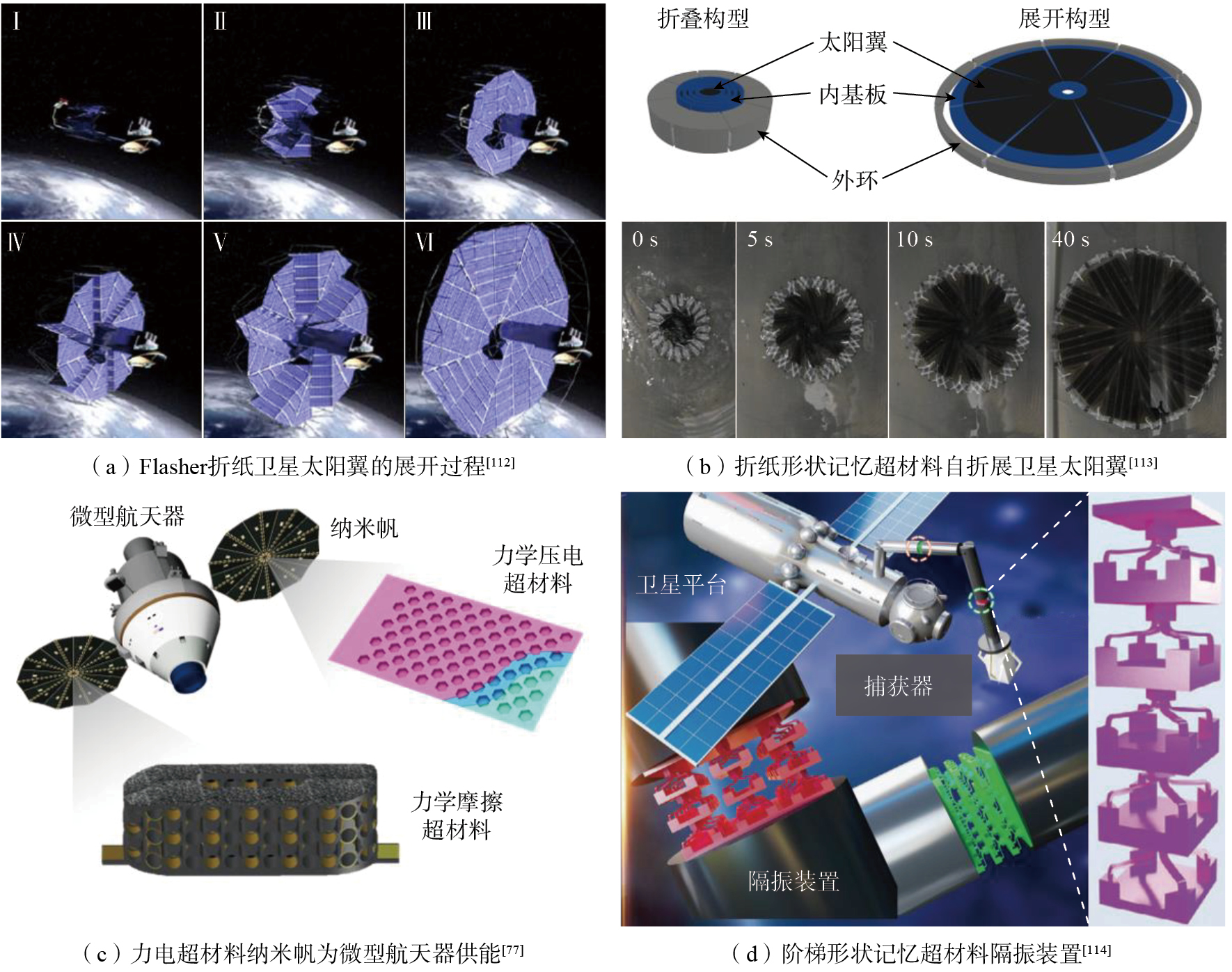

力学超材料是一类人造结构化材料,其本质是以人工微结构为单元构造的复合结构,旨在通过设计人工微结构单元的形状、尺寸和周期性排列模式增强宏观整体结构的力学性能,实现负泊松比、多稳态、轻质高强、可编程/重编程等超常力学性能。然而,通过常规材料制备的力学超材料难以满足不同工程应用场景对功能器件的多环境场自适应性、迅速可控环境响应和能量转化等性能要求。结合力学超材料和先进功能材料构筑的力学功能超材料从材料角度拓展了力学超材料的性能,可以实现可调控的力电、力磁、力热等耦合响应,有望实现力学超材料的多功能工程应用。本文从超常力学性能和典型分类方面阐述了力学超材料的研究进展,从构筑方法和耦合响应方面详细介绍了力电、力磁和力热超材料3类代表性力学功能超材料,总结与展望了力学功能超材料在航空航天和海洋工程领域的潜在工程应用,包括自折展卫星太阳翼、微型航天器自供能、卫星平台隔振、海洋工程与装备监测感知和海洋波浪能采集等。

关键词

力学功能超材料;力学超材料;功能材料;航空航天;海洋工程;

Research Progress of Mechanically Functional Metamaterials Towards Multifunctional Engineering Applications

Citations

MAO Zhenjun, XU Haibo, TENG Yuan, et al. Research progress of mechanically functional metamaterials towards multifunctional engineering applications[J]. Aeronautical Manufacturing Technology, 2025, 68(15): 47–62.

Abstract

Mechanical metamaterials are a category of artificial structural materials and essentially composite structures constructed with artificial microstructure units, which aim to enhance mechanical properties of macroscopic overall structure by designing the shape, size and periodic arrangement mode of artificial microstructure units, and to achieve extraordinary mechanical properties such as negative Poisson’s ratio, multi-stability, lightweight and high strength, and programmability/reprogrammability. However, mechanical metamaterials fabricated by conventional materials are difficult to meet the performance requirements of multi-environmental field adaptability, rapid and controllable environmental response, and energy conversion for functional devices in different engineering application scenarios. Mechanically functional metamaterials constructed by combining mechanical metamaterials with advanced functional materials expand the performance of mechanical metamaterials from the material perspective, and can achieve tunable electro-mechanical, magneto-mechanical and thermo-mechanical coupling responses, which are expected to realize the multifunctional engineering applications of mechanical metamaterials. This review describes the extraordinary mechanical properties and typical classifications of mechanical metamaterials, detailly introduce the construction methods and coupling responses of three representative mechanically functional metamaterials, namely electro-mechanical, magneto-mechanical and thermo-mechanical metamaterials, and summarizes and prospects the potential engineering applications of mechanically functional metamaterials in the fields of aerospace and marine engineering, including self-folding satellite solar wings, micro-spacecraft self-powered, satellite platform vibration isolation, marine engineering and equipment monitoring and sensing, and marine wave energy harvesting.

Keywords

Mechanically functional metamaterials

超材料是一类人造结构化材料,由人工微结构单元在二维或三维空间中周期性拓展形成。通过设计人工微结构单元的形状、尺寸和周期性排列模式,可以获得天然材料前所未有、难以实现的特性、功能和应用[

KADIC M, MILTON G W, VAN HECKE M, et al. 3D metamaterials[J]. Nature Reviews Physics, 2019, 1(3): 198–210.

JIAO P C, ALAVI A H. Artificial intelligence-enabled smart mechanical metamaterials: Advent and future trends[J]. International Materials Reviews, 2021, 66(6): 365–393.

1-3

4

5

6

7

8

尹剑飞, 蔡力, 方鑫, 等. 力学超材料研究进展与减振降噪应用[J]. 力学进展, 2022, 52(3): 508–586.YIN Jianfei, CAI Li, FANG Xin, et al. Review on research progress of mechanical metamaterials and their applications in vibration and noise control[J]. Advances in Mechanics, 2022, 52(3): 508–586.

9-10

先进功能材料可定义为具有一种或多种电、磁、光、热、形状记忆等功能的特种材料。上述功能可以通过电场、磁场、光、温度、生化等特定外部激励激发和调控。功能材料几乎在所有材料(金属、陶瓷、聚合物等)中存在,近年来广泛应用在科学技术、工农业等领域中[

11

12

13

14

15

16

17

本文介绍了力学超材料的定义、超常力学性能和典型分类。按照超常力学性能分类,常见的力学超材料类别有负泊松比力学超材料、多稳态力学超材料、轻质高强力学超材料、可编程/重编程力学超材料等。归纳了典型力学功能超材料的构筑方法和多环境场耦合响应。常见的力学功能超材料有力电超材料、力磁超材料和力热超材料。以航空航天和海洋工程领域为例,总结和展望了力学功能超材料的潜在工程应用,包括自折展卫星太阳翼、微型航天器自供能、卫星平台隔振、海洋工程与装备监测感知、海洋波浪能收集等。本文从概念、构筑方法、耦合响应、潜在工程应用等方面为力学功能超材料的研究进展提供了一份前沿、全面和精炼的科学综述,为该领域未来的研究方向和发展趋势提供参考。

力学超材料是一类人造结构化材料,其本质是以人工微结构为单元构造的复合结构[

18

19

20

21

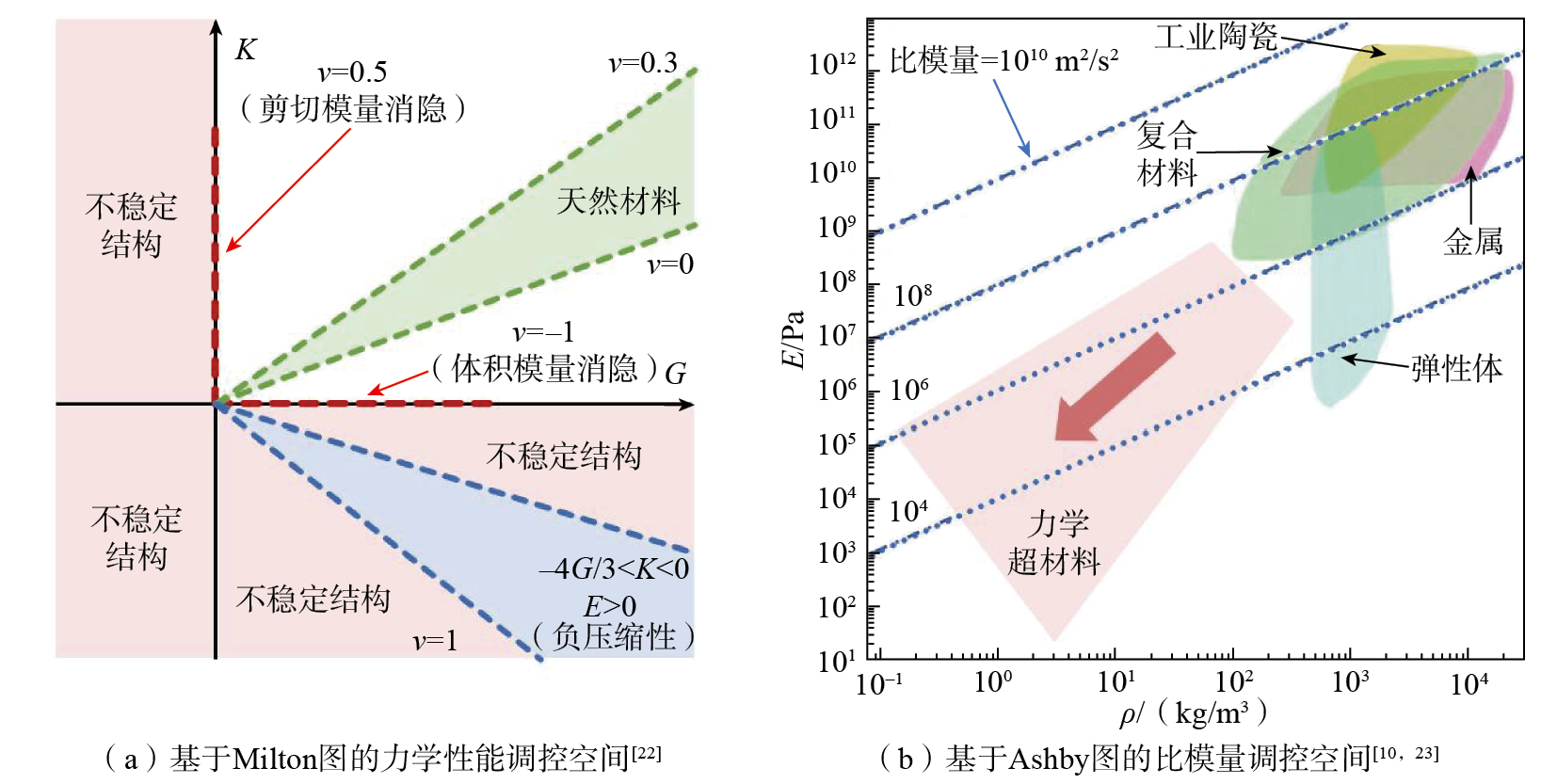

弹性固体材料的力学性能一般通过以下4个基本力学参数表征:杨氏模量E、体积模量K、剪切模量G和泊松比ν,它们之间相互关联、制约。例如,各向同性弹性固体材料通常符合K/G=[2(ν+1)]/[3(1–2ν)]的规律[

19

22

10

23

力学超材料的分类方式不是唯一、绝对的,常见的分类依据有超常力学性能、调控的弹性模量、人工微结构单元构型等[

24

25

26

27

28

JIAO P C, CHEN Z C, WANG J J. Origami metamaterial biomimetic bouquets expand floriography to spatiotemporal 4D[J]. Cell Reports Physical Science, 2024, 5(4): 101921.

ZHANG H Y, PAIK J. Kirigami design and modeling for strong, lightweight metamaterials[J]. Advanced Functional Materials, 2022, 32(21): 2107401.

FANG X, WEN J H, CHENG L, et al. Programmable gear-based mechanical metamaterials[J]. Nature Materials, 2022, 21(8): 869–876.

25-28

负泊松比定义为材料在轴向拉伸(压缩)下发生侧向膨胀(收缩)的性质。区别于传统正泊松比材料,负泊松比力学超材料通常具有增强的抗剪切、抗断裂、能量吸收等性能[

吴文旺, 肖登宝, 孟嘉旭, 等. 负泊松比结构力学设计、抗冲击性能及在车辆工程应用与展望[J]. 力学学报, 2021, 53(3): 611–638.WU Wenwang, XIAO Dengbao, MENG Jiaxu, et al. Mechanical design, impact energy absorption and applications of auxetic structures in automobile lightweight engineering[J]. Chinese Journal of Theoretical and Applied Mechanics, 2021, 53(3): 611–638.

29-30

31

32

33

34

35

36

FANG S T, ZHOU S X, YURCHENKO D, et al. Multistability phenomenon in signal processing, energy harvesting, composite structures, and metamaterials: A review[J]. Mechanical Systems and Signal Processing, 2022, 166: 108419.

37-38

39

40

41

42

43

44

45

46

47

ZHAI Z R, WU L L, JIANG H Q. Mechanical metamaterials based on origami and kirigami[J]. Applied Physics Reviews, 2021, 8(4): 041319.

48-49

TAHIDUL HAQUE A B M, FERRACIN S, RANEY J R. Reprogrammable mechanics via individually switchable bistable unit cells in a prestrained chiral metamaterial[J]. Advanced Materials Technologies, 2024, 9(17): 2400474.

50-51

52

53

54

55

56

JIAO P C, CHEN Z C, WANG J J. Origami metamaterial biomimetic bouquets expand floriography to spatiotemporal 4D[J]. Cell Reports Physical Science, 2024, 5(4): 101921.

25-26

28

GREGG C E, CATANOSO D, FORMOSO O I B, et al. Ultralight, strong, and self-reprogrammable mechanical metamaterials[J]. Science Robotics, 2024, 9(86): eadi2746.

54-55

YIN S, GUO W H, WANG H T, et al. Strong and tough bioinspired additive-manufactured dual-phase mechanical metamaterial composites[J]. Journal of the Mechanics and Physics of Solids, 2021, 149: 104341.

YAO Y, ZHOU Y, CHEN L H, et al. A multifunctional three-dimensional lattice material integrating auxeticity, negative compressibility and negative thermal expansion[J]. Composite Structures, 2024, 337: 118032.

DUDEK K K, IGLESIAS MARTÍNEZ J A, ULLIAC G, et al. Micro-scale mechanical metamaterial with a controllable transition in the Poisson’s ratio and band gap formation[J]. Advanced Materials, 2023, 35(20): 2210993.

LI Z Y, GAO W, WANG M Y, et al. Three-dimensional metamaterials exhibiting extreme isotropy and negative Poisson’s ratio[J]. International Journal of Mechanical Sciences, 2023, 259: 108617.

DU L M, SHI W, GAO H, et al. Mechanically programmable composite metamaterials with switchable positive/negative Poisson’s ratio[J]. Advanced Functional Materials, 2024, 34(22): 2314123.

XU X, HUANG C Q, LI C C, et al. Adjustable ultra-light mechanical negative Poisson’s ratio metamaterials with multi-level dynamic crushing effects[J]. Small, 2024, 20(43): 2470312.

ZHOU W, WANG Y Z. Cooperative propagation and directional phase transition of topological solitons in multi-stable mechanical metamaterials[J]. Journal of the Mechanics and Physics of Solids, 2023, 175: 105287.

JIAO W J, SHU H, TOURNAT V, et al. Phase transitions in 2D multistable mechanical metamaterials via collisions of soliton-like pulses[J]. Nature Communications, 2024, 15(1): 333.

HE J, WANG Y H, SHEN Z Q, et al. Assembled mechanical metamaterials with integrated functionalities of programmable multistability and multitransition behaviors[J]. Materials Horizons, 2024, 11(24): 6371–6380.

XU R, HE Y L, CHEN C Q, et al. Rotation-based snap-fit mechanical metamaterials[J]. Advanced Science, 2025: 2501749.

XING Y R, LUO L S, LI Y S, et al. Exploration of hierarchical metal-organic framework as ultralight, high-strength mechanical metamaterials[J]. Journal of the American Chemical Society, 2022, 144(10): 4393–4402.

CHENG H W, ZHU X X, CHENG X W, et al. Mechanical metamaterials made of freestanding quasi–BCC nanolattices of gold and copper with ultra-high energy absorption capacity[J]. Nature Communications, 2023, 14: 1243.

LI Y W, JIN H X, ZHOU W J, et al. Ultrastrong colloidal crystal metamaterials engineered with DNA[J]. Science Advances, 2023, 9(39): eadj8103.

ZHONG H Z, DAS R, GU J F, et al. Low-density, high-strength metal mechanical metamaterials beyond the Gibson-Ashby model[J]. Materials Today, 2023, 68: 96–107.

57-71

72

73

74

| 力学超材料类别 | 力学超材料名称及参考文献(年份) | 力学性能指标 |

|---|---|---|

| 负泊松比力学超材料 | 基于三角形元素的微尺度力学超材料[ 57 |

泊松比–1.4 |

| 极端各向同性与负泊松比超材料[ 58 |

泊松比–1 | |

| 具有无孔结构与坚固界面的集成双相负泊松比复合超材料[ 59 |

泊松比–0.5 | |

| Z形韧带手性方体[ 25 |

泊松比–0.69 | |

| 具有多级动态破碎效应的可调超轻负泊松比超材料[ 60 |

泊松比–0.73 | |

| 多稳态力学超材料 | 基于六边形块体的多稳态力学超材料[ 61 |

— |

| 基于类弧子脉冲碰撞的二维多稳态力学超材料[ 62 |

— | |

| 组装力学超材料[ 63 |

— | |

| 仿百合半球形折纸超材料[ 26 |

— | |

| 基于旋转的卡扣式力学超材料[ 64 |

— | |

| 轻质高强力学超材料 | 基于分级金属有机骨架的力学超材料[ 65 |

比强度(0.68±0.11)GPa/(g·cm3) |

| 金属准体心立方纳米晶格[ 66 |

相对密度<0.5 | |

| (107±11)MPa(金基材屈服强度);(153±15)MPa(铜基材屈服强度) | ||

| DNA组装的超强胶体晶体超材料[ 67 |

比强度125 MPa/(g·cm–3) | |

| 比刚度550 MPa/(g·cm–3) | ||

| Ti–6Al–4V晶格[ 68 |

密度1.6 g/cm3 | |

| 强度>400 MPa | ||

| 基于纤维增强复合材料桁架状构件的晶格力学超材料[ 55 |

比强度1.1049 MPa/(g·cm–3) | |

| 比刚度108.0485 MPa/(g·cm–3) | ||

| 可编程/重编程力学超材料 | 可编程齿轮力学超材料[ 28 |

杨氏模量调制范围达两个数量级 |

| 4D像素力学超材料[ 54 |

机械像素的应力–应变关系可调制、可编程、可重构 | |

| 多稳态拓扑麦克斯韦晶格[ 69 |

宏观尺度结构构型可编程,刚度可调制,拓扑转变 | |

| 可编程数字力学超材料[ 70 |

压缩下单元呈现压缩–扭转耦合、压缩–剪切耦合和纯压缩3种可编程变形 | |

| 基于可变形多面体模块的力学超材料[ 71 |

单向载荷下呈现正负泊松比复杂交替变化 |

本节从超常力学性能和典型分类方面阐述了力学超材料的研究进展。力学超材料表现出超越天然材料的非常规和可调控的力学性能,在各种力学相关工程中有巨大的应用潜力。现阶段,力学超材料领域的研究主要关注: (1)力学超材料人工微结构单元和整体结构设计; (2)力学超材料超常力学性能的探索与表征; (3)力学超材料器件的潜在和实际应用。此外,由于理论建模困难、试验制备与测试价格昂贵、数值仿真计算成本较高等因素使人类对力学超材料的进一步探索受到了限制[

3

75

76

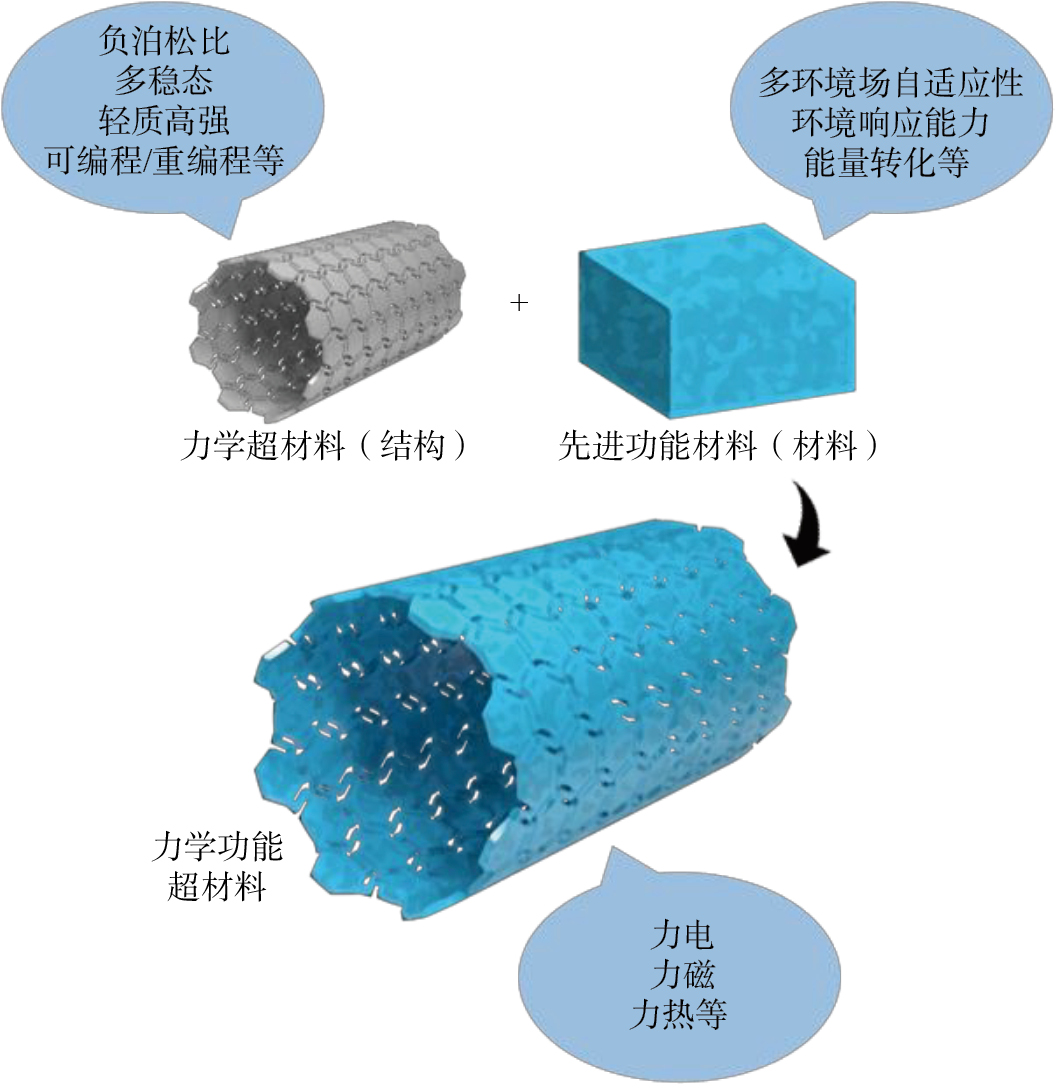

力学功能超材料是结合力学超材料和先进功能材料构筑的一类多功能复合材料,旨在超越力学超材料的非常规力学性能,以获得可控的力电、力磁、力热等超常耦合响应,实现力学超材料的多功能工程应用。在结构方面,力学功能超材料承继了力学超材料的超常力学响应、力学性能可调控等优势。在材料方面,力学功能超材料兼具了先进功能材料的多环境场自适应性、环境响应能力、能量转化等特性,图3展示了力学功能超材料的构筑原理。力学功能超材料可以根据耦合响应进行分类,下文将分别介绍具有力电、力磁和力热响应的力学功能超材料。

力电超材料指选用电学功能材料为材料基质的力学功能超材料,它们可以将外界环境的机械能转化为电能,实现能量收集、监测感知等功能[

77

BARRI K, JIAO P C, ZHANG Q Y, et al. Multifunctional meta-tribomaterial nanogenerators for energy harvesting and active sensing[J]. Nano Energy, 2021, 86: 106074.

BARRI K, ZHANG Q Y, SWINK I, et al. Patient-specific self-powered metamaterial implants for detecting bone healing progress[J]. Advanced Functional Materials, 2022, 32(32): 2203533.

BARRI K, ZHANG Q Y, KLINE J, et al. Multifunctional nanogenerator-integrated metamaterial concrete systems for smart civil infrastructure[J]. Advanced Materials, 2023, 35(14): e2211027.

XIA K Q, LIU J Z, LI W T, et al. A self-powered bridge health monitoring system driven by elastic origami triboelectric nanogenerator[J]. Nano Energy, 2023, 105: 107974.

ZHANG Q Y, BARRI K, JIAO P C, et al. Meta-mechanotronics for self-powered computation[J]. Materials Today, 2023, 65: 78–89.

78-83

JIAO P C, HASNI H, LAJNEF N, et al. Mechanical metamaterial piezoelectric nanogenerator (MM–PENG): Design principle, modeling and performance[J]. Materials & Design, 2020, 187: 108214.

JIAO P C, YANG Y, EGBE K I, et al. Mechanical metamaterials gyro-structure piezoelectric nanogenerators for energy harvesting under quasi-static excitations in ocean engineering[J]. ACS Omega, 2021, 6(23): 15348–15360.

HONG L Q, ZHANG H, KRAUS T, et al. Ultra-stretchable kirigami piezo-metamaterials for sensing coupled large deformations[J]. Advanced Science, 2024, 11(5): 2303674.

84-87

88

89

Barri等[

80

78

85

87

78

XIA K Q, LIU J Z, LI W T, et al. A self-powered bridge health monitoring system driven by elastic origami triboelectric nanogenerator[J]. Nano Energy, 2023, 105: 107974.

81-82

84

87

WANG Z H, CHENG J, XIE Y, et al. Lead-free piezoelectric composite based on a metamaterial for electromechanical energy conversion[J]. Advanced Materials Technologies, 2022, 7(12): 2200650.

AHMADPOUR A, YETISEN A K, TASOGLU S. Piezoelectric metamaterial blood pressure sensor[J]. ACS Applied Electronic Materials, 2023, 5(6): 3280–3290.

SHI J H, JU K, CHEN H Y, et al. Ultrahigh piezoelectricity in truss-based ferroelectric ceramics metamaterials[J]. Advanced Functional Materials, 2025, 35(12): 2417618.

91-94

| 力电超材料类别 | 力电超材料名称及参考文献(年份) | 性能指标 | ||

|---|---|---|---|---|

| 开路电压 | 短路电流 | 最大输出功率(密度) | ||

| 力学摩擦超材料 | 力学摩擦超材料混凝土集成系统[ 81 |

14 V | 236 nA | 330 µW |

| 基于弹性折纸的折纸摩擦超材料[ 82 |

105 V | 58 μA | 162 µW | |

| 基于Kresling折纸的折纸摩擦超材料[ 78 |

206.4 V | 4.66 μA | 0.96 μW/cm² | |

| 基于杨氏模量可调力学超材料的自感知力学摩擦超材料[ 90 |

11.76 mV | 16.67 pA | — | |

| 具有单向电荷转移通道的力学摩擦超材料[ 91 |

3860 V | 8 µA | 365.3 kW/m3 | |

| 力学压电超材料 | PVDF剪纸薄膜[ 84 |

340 mV | — | — |

| 基于3D打印有序超材料结构骨架的压电复合材料[ 92 |

21.7 V | — | 17 µW/cm2 | |

| 二维晶格压电超材料[ 93 |

1123 mV | — | — | |

| 具有规则韧带的剪纸压电超材料[ 87 |

24.6 V | 117.85 nA | — | |

| 基于桁架结构的铁电陶瓷超材料[ 94 |

101 V | — | 5.09 mW/cm3 | |

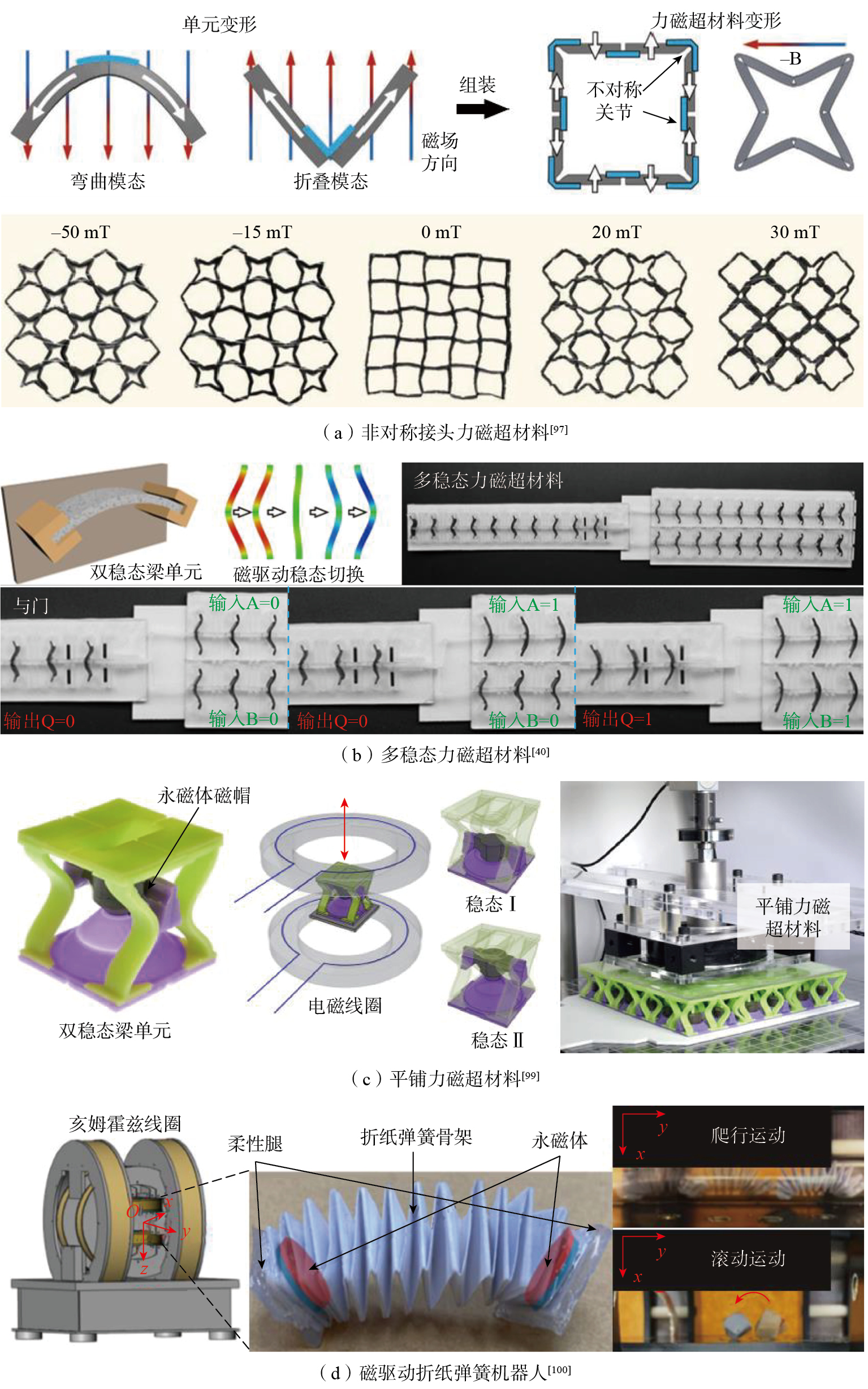

力磁超材料定义为以磁响应活性材料为材料基质的力学功能超材料,可以通过迅速、连续地响应磁场环境,实现可控、可逆的形状变换,目前广泛应用于磁驱执行器、磁驱机器人、生物医学等领域[

95

MONTGOMERY S M, WU S, KUANG X, et al. Magneto-mechanical metamaterials with widely tunable mechanical properties and acoustic bandgaps[J]. Advanced Functional Materials, 2021, 31(3): 2005319.

ZHU H L, WANG Y, GE Y W, et al. Kirigami-inspired programmable soft magnetoresponsive actuators with versatile morphing modes[J]. Advanced Science, 2022, 9(32): 2203711.

96-98

YUAN S S, CAO S F, XUE J N, et al. Versatile motion generation of magnetic origami spring robots in the uniform magnetic field[J]. IEEE Robotics and Automation Letters, 2022, 7(4): 10486–10493.

ZOU B H, LIANG Z H, ZHONG D J, et al. Magneto-thermomechanically reprogrammable mechanical metamaterials[J]. Advanced Materials, 2023, 35(8): 2207349.

99-101

Montgomery等[

97

40

99

100

力热超材料是一类利用温度响应活性材料制备的力学功能超材料,可以迅速、连续地响应温度环境,实现可控、可逆的形状变化,此类材料适用于开发热驱执行器、热驱机器人、温度传感设备等[

88

LI X J, WANG L L, LI Y W, et al. Reprocessable, self-healing, thermadapt shape memory polycaprolactone via robust ester–ester interchanges toward kirigami-tailored 4D medical devices[J]. ACS Applied Polymer Materials, 2023, 5(2): 1585–1595.

YANG H, D’AMBROSIO N, LIU P Y, et al. Shape memory mechanical metamaterials[J]. Materials Today, 2023, 66: 36–49.

102-104

YANG N, ZHANG M K, ZHU R. 3D kirigami metamaterials with coded thermal expansion properties[J]. Extreme Mechanics Letters, 2020, 40: 100912.

JIAO P C, HONG L Q, WANG J J, et al. Self-triggered thermomechanical metamaterials with asymmetric structures for programmable response under thermal excitations[J]. Materials, 2021, 14(9): 2177.

105-107

王瑞晨, 刘秀军, 张静, 等. 刺激响应形状记忆材料的4D打印及其研究进展[J]. 功能材料, 2021, 52(10): 10069–10074.WANG Ruichen, LIU Xiujun, ZHANG Jing, et al. Recent progress in 4D printing of stimulus-responsive shape memory materials[J]. Journal of Functional Materials, 2021, 52(10): 10069–10074.

108-109

110

Li等[

103

104

105

本节从构筑方法和耦合响应方面介绍了力电、力磁和力热超材料3类代表性力学功能超材料。力学功能超材料融合了力学超材料和先进功能材料的优势和特性,从材料角度来看,增强、拓展和超越了力学超材料的非常规力学性能,推动了力学超材料器件的性能提升和应用。现阶段,力学功能超材料的研究主要关注:(1)力学功能超材料制备工艺的研发;(2)力学功能超材料的构筑,包括力学超材料结构设计、功能材料选择等;(3)力学功能超材料超常耦合响应和功能的探索、分析与表征。然而,现有研究通常通过简单叠加力学超材料和功能材料构筑力学功能超材料,鲜有报道研究力学超材料结构设计对功能材料性能的影响和增益。因此,在构筑力学功能超材料时,需要重点关注力学超材料(结构)和功能材料(材料)的有机结合,实现力学超材料超常力学响应对功能材料性能的增益,产生1+1>2的倍增效果。

力学功能超材料融合了力学超材料和先进功能材料的超常力学响应、力学性能可调控、多环境场自适应性、能量转化等优势,表现出可控的力电、力磁、力热等超常耦合响应,有望广泛应用于航空航天、海洋工程、能源工程等领域,为诸多工程领域提供解决策略。下文以航空航天和海洋工程为例,总结和展望了力学功能超材料的潜在工程应用,包括自折展卫星太阳翼、微型航天器自供能、卫星平台隔振、海上风电与跨海桥梁等海洋工程与装备监测感知、海洋波浪能收集等。

折纸力学超材料已用于卫星太阳翼、固面天线、空间望远镜等空间折展结构的设计中[

111

112

113

77

114

力学摩擦超材料、力学压电超材料等力电超材料将机械能转化为电能的特性使它们可以实现海上风电与跨海桥梁等海洋工程与装备监测感知、海洋波浪能收集等应用。Li等[

115

78

78

JIAO P C, YANG Y, EGBE K I, et al. Mechanical metamaterials gyro-structure piezoelectric nanogenerators for energy harvesting under quasi-static excitations in ocean engineering[J]. ACS Omega, 2021, 6(23): 15348–15360.

85-86

由于缺乏针对力学功能超材料的大尺度和微纳尺度一体化制备工艺,以及力学功能超材料自身难以完成的工程应用中需要的全部功能和技术,导致力学功能超材料的工程应用仍然处在设想和实验室验证阶段。为了实现力学功能超材料的实际工程应用,目前需要重点关注:(1)研发力学功能超材料的大尺度和微纳尺度一体化制备工艺,实现力学功能超材料的高效、高质量制造。相较于独立制备大型力学功能超材料器件的局部构件并组装形成整体器件,大尺度一体化制备工艺将极大节约制造时间和成本。为了准确控制和预测力学功能超材料的多环境场耦合响应,精确制造小型力学功能超材料局部结构的微纳尺度一体化制备工艺是必要的技术前提;(2)设计和研发融合多种技术和设备的力学功能超材料集成系统。力学功能超材料自身难以实现工程应用,因此需要开发融合其他技术和设备的力学功能超材料集成系统。例如,为了存储和利用力学超材料纳米帆采集电能,真正实现微型航天器的供能,微型航天器需要搭载额外的能量存储设备,与力电超材料纳米帆构成力电超材料集成供能系统。

力学超材料可以实现负泊松比、多稳态、轻质高强、可编程/重编程等超常力学性能。然而,以常规材料为材料基质的力学超材料难以满足不同工程应用场景对功能器件的多环境场自适应性、迅速可控环境响应和能量转化等性能要求。结合力学超材料和先进功能材料构筑力学功能超材料,可以超越力学超材料的非常规力学性能,获得可控的力电、力磁、力热等超常耦合响应,为力学超材料的多功能工程应用提供有效解决策略。本文深入探讨了力电、力磁和力热超材料3类代表性力学功能超材料的构筑方法和耦合响应,以及力学功能超材料在航空航天和海洋工程领域的多功能工程应用,包括自折展卫星太阳翼、微型航天器自供能、卫星平台隔振、海洋工程与装备监测感知和海洋波浪能采集等。根据力学功能超材料的研究现状,提出以下挑战和趋势。

截至目前,大多数现有研究仍然停留在以机理研究和实验室测试为主的实验室阶段,缺乏实现实际应用的力学功能超材料器件。据分析,力学功能超材料在应用层面面临的挑战和难题主要有以下4个方面。

(1)现有研究通常通过简单叠加力学超材料(结构)和先进功能材料(材料)构筑力学功能超材料,鲜有报道关注力学超材料结构设计对功能材料性能的增益,例如增大能量转化率、提升放大形变等。

(2)目前缺乏大尺度制备工艺一体化制造大型力学功能超材料器件,而独立制备力学功能超材料器件的局部构件并组装形成整体器件将大大增加制造时间和成本,导致实现自折展卫星太阳翼、卫星平台隔振等应用难度巨大、成本高昂。

(3)目前缺乏微纳尺度一体化工艺精确制造小型力学功能超材料的局部结构,难以准确控制和预测力学功能超材料的多环境场耦合响应,限制了微型航天器自供能、海上风电与跨海桥梁等海洋工程与装备监测感知、海洋波浪能收集等应用。

(4)力学功能超材料自身难以完成工程应用需要的全部功能和技术,例如力电超材料纳米帆、波纹压电超材料能量采集器等力电超材料器件可以将环境中的机械能转化为电能,而无法独自储存转化的电能,以备在未来随时利用。

针对力学功能超材料面临的挑战和难题,力学功能超材料的未来研究应致力于提出能够有效增强功能材料性能的力学超材料结构设计,研发针对大尺度与微纳尺度力学功能超材料器件的制备工艺,以及开发融合多种技术和设备的力学功能超材料集成系统。首先,根据应用场景和所选功能材料特点,设计可以有效增强功能材料性能的力学超材料结构,实现力学超材料的超常力学响应对功能材料的多环境场自适应性、能量转化等性能的增益,产生1+1>2的倍增效果;其次,针对拟制造的力学功能超材料器件的尺寸、结构特点和材料组成,研发大尺度与微纳尺度的先进多材料、一体化制备工艺,缩减制造时间和成本,提升制造精度;最后,根据应用需求和力学功能超材料特性,设计和研发融合其他技术和设备的力学功能超材料集成系统,为力学功能超材料器件的实际应用铺平道路。

| 毛振军 正高级工程师,研究方向为力学功能超材料。 |

参考文献

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] | |

| [35] | |

| [36] | |

| [37] | |

| [38] | |

| [39] | |

| [40] | |

| [41] | |

| [42] | |

| [43] | |

| [44] | |

| [45] | |

| [46] | |

| [47] | |

| [48] | |

| [49] | |

| [50] | |

| [51] | |

| [52] | |

| [53] | |

| [54] | |

| [55] | |

| [56] | |

| [57] | |

| [58] | |

| [59] | |

| [60] | |

| [61] | |

| [62] | |

| [63] | |

| [64] | |

| [65] | |

| [66] | |

| [67] | |

| [68] | |

| [69] | |

| [70] | |

| [71] | |

| [72] | |

| [73] | |

| [74] | |

| [75] | |

| [76] | |

| [77] | |

| [78] | |

| [79] | |

| [80] | |

| [81] | |

| [82] | |

| [83] | |

| [84] | |

| [85] | |

| [86] | |

| [87] | |

| [88] | |

| [89] | |

| [90] | |

| [91] | |

| [92] | |

| [93] | |

| [94] | |

| [95] | |

| [96] | |

| [97] | |

| [98] | |

| [99] | |

| [100] | |

| [101] | |

| [102] | |

| [103] | |

| [104] | |

| [105] | |

| [106] | |

| [107] | |

| [108] | |

| [109] | |

| [110] | |

| [111] | |

| [112] | |

| [113] | |

| [114] | |

| [115] |