氮化硅陶瓷在航空航天领域的研究进展及应用

通信作者:

梁静静,研究员,博士,研究方向为增材制造高温合金和复杂结构陶瓷材料。

李乔磊,助理研究员,博士,研究方向为增材制造高温陶瓷材料及单晶叶片制备。

基金项目:

国家自然科学基金(52402094,U234120139,U22A20129);国防基础科研计划(JCKY2022130C005);中国博士后科学基金(2023M743571);国家资助博士后研究人员计划(GZC20232743);中国科学院金属研究所创新基金(2024–PY11);高端装备铸造技术全国重点实验室开放基金(CAT2023–006);安徽省研究生教育质量工程(2023cxcyjs015);国家重点研发计划(2018YFB1106600)。

中图分类号:

V25

文献标识码:

A

引文格式:

滕家琛, 李乔磊, 梁静静, 等. 氮化硅陶瓷在航空航天领域的研究进展及应用[J]. 航空制造技术, 2025, 68(12): 106-120.

摘要

氮化硅陶瓷凭借其耐高温、耐磨损、高强度和优异的抗热冲击性能,已成为涡轮叶片、热防护系统和航空航天结构件的理想材料。然而,随着航空航天结构件向更高服役温度和轻量化方向的发展,氮化硅陶瓷在成型和性能方面的不足逐渐显现。此外,现有的性能检测多集中于常温、常压、瞬时状态等工况,难以反映氮化硅陶瓷在航空航天领域的真实服役性能,亟须改进。为解决这些问题,本文详细阐述了近年来氮化硅陶瓷在成型、性能检测、微观结构调控和力学性能等方面的研究进展,探讨该材料在航空航天领域的应用现状,并提出相关建议以推动氮化硅陶瓷在航空航天领域的创新与发展。

关键词

氮化硅;成型工艺;力学性能;微观结构调控;强韧化;

Research Progress and Application of Silicon Nitride Ceramics in Aerospace Field

Citations

TENG Jiachen, LI Qiaolei, LIANG Jingjing, et al. Research progress and application of silicon nitride ceramics in aerospace field[J]. Aeronautical Manufacturing Technology, 2025, 68(12): 106-120.

Abstract

Silicon nitride (Si3N4) ceramics are ideal materials for turbine blades, thermal protection systems and aerospace structural components due to their high-temperature resistance, wear resistance, high strength and excellent thermal shock resistance. However, with the development of aerospace structural components towards higher service temperature and lightweight, shortcomings of Si3N4 ceramics in terms of molding and performance gradually appears. In addition, the existing performance tests mostly focus on working conditions of normal temperature, normal pressure, and transient state, which are not being able to reflect the real service performance of Si3N4 ceramics in aerospace field, therefore need to be improved urgently. To address these problems, this paper elaborates the research progress of Si3N4 ceramics in the aspects of molding, performance testing, microstructure control and mechanical properties, discusses the current status of Si3N4 ceramic application and puts forward relevant suggestions to promote innovation and development of Si3N4 ceramics in aerospace.

Keywords

Silicon nitride

氮化硅陶瓷是由氮原子和硅原子通过共价键紧密结合形成的化合物,得益于共价键的特性,氮化硅陶瓷展现出高温高强度、耐腐蚀、耐磨损及优异的抗热震性能[

DA SILVA C R M, REIS D A P, DOS SANTOS C. Creep of heat treated silicon nitride with neodymium and yttrium oxides additions[J]. Materials Science and Engineering: A, 2010, 527(26): 6893–6898.

MELÉNDEZ-MARTÍNEZ J J, DOMÍNGUEZ-RODRÍGUEZ A. Creep of silicon nitride[J]. Progress in Materials Science, 2004, 49(1): 19–107.

1-3

4

ZOU R F, BI L N, HUANG Y, et al. A biocompatible silicon nitride dental implant material prepared by digital light processing technology[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2023, 141: 105756.

5-6

7

TATAMI J, UDA M, TAKAHASHI T, et al. Microscopic mechanical properties of silicon nitride ceramics corroded in sulfuric acid solution[J]. Journal of the European Ceramic Society, 2024, 44(9): 5415–5421.

8-9

10

近年来,氮化硅陶瓷的研究在微观机理和成型工艺方面取得重要进展,为其性能提升及应用奠定了坚实基础。Zhang等[

11

12

13

随着航空航天领域的快速发展,更严苛的服役环境对氮化硅的结构和性能提出了更高要求。然而,目前氮化硅陶瓷在成型工艺和性能提升方面仍然存在瓶颈问题[

WANG C M, PAN X Q, RÜHLE M, et al. Silicon nitride crystal structure and observations of lattice defects[J]. Journal of Materials Science, 1996, 31(20): 5281–5298.

JANG J, LEE Y, CHEONG H, et al. Defects and mechanical properties of silicon nitride ball bearings for electric vehicle reducers[J]. World Electric Vehicle Journal, 2024, 15(6): 272.

14-16

为克服上述问题,亟须通过改进成型工艺、组织结构、热处理方式来提升氮化硅的整体性能。其中,了解氮化硅陶瓷的研究进展尤为重要,通过掌握最新研究内容,不仅能够了解国内外氮化硅陶瓷的性能现状,还能为现有技术难题提供解决思路。因此,本文对近年来氮化硅陶瓷的研究进行了系统综述,主要包括氮化硅陶瓷的成型工艺、性能检测方法、性能调控研究及在航空航天领域的应用。通过对当前研究现状的系统分析,展望了氮化硅陶瓷在航空航天领域的发展前景,并提出相关建议。

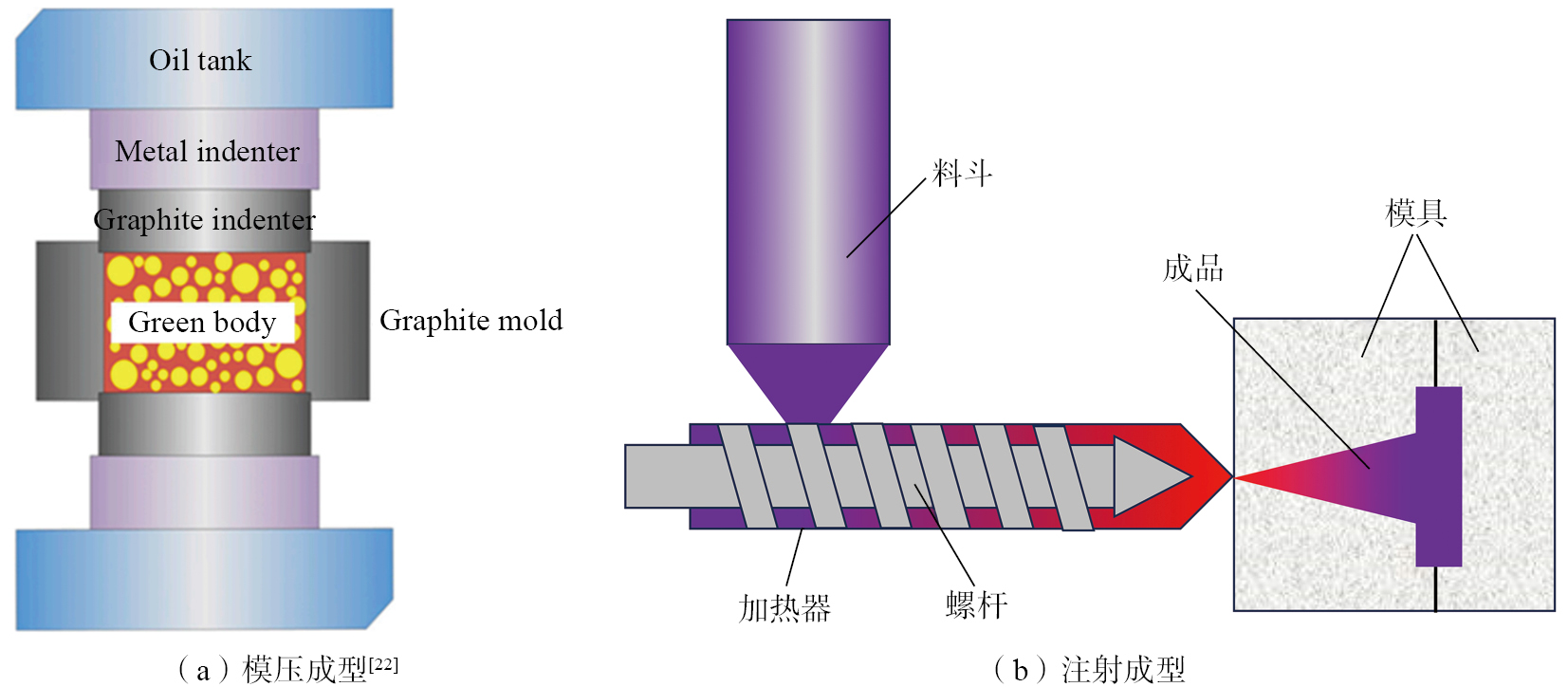

航空航天结构件需具备复杂结构、高精度及良好的表面质量,这对氮化硅陶瓷的成型技术提出较高要求。了解氮化硅陶瓷的成型方式及优缺点对其成型工艺的改进及生产具有一定指导意义。目前氮化硅陶瓷的成型工艺主要包括模压成型、注射成型、挤出成型、光固化3D打印成型、熔融沉积成型等[

冯相蓺, 任桂莹, 王东, 等. 光固化3D打印氮化硅陶瓷研究进展[J]. 材料导报, 2023, 37(S2): 109–114.FENG Xiangyi, REN Guiying, WANG Dong, et al. Research progress of light-cured 3D printed silicon nitride ceramics[J]. Materials Reports, 2023, 37(S2): 109–114.

周庆旋, 汪洋, 韩卓群, 等. 氮化硅陶瓷光固化3D打印成形研究进展[J]. 硅酸盐通报, 2024, 43(5): 1588–1599.ZHOU Qingxuan, WANG Yang, HAN Zhuoqun, et al. Research progress of stereolithography 3D printing of silicon nitride ceramics[J]. Bulletin of the Chinese Ceramic Society, 2024, 43(5): 1588–1599.

IYER S, MCINTOSH J, BANDYOPADHYAY A, et al. Microstructural characterization and mechanical properties of Si3N4 formed by fused deposition of ceramics[J]. International Journal of Applied Ceramic Technology, 2008, 5(2): 127–137.

RANGARAJAN S, QI G, VENKATARAMAN N, et al. Powder processing, rheology, and mechanical properties of feedstock for fused deposition of Si3N4 ceramics[J]. Journal of the American Ceramic Society, 2000, 83(7): 1663–1669.

17-21

| 陶瓷成型工艺 | 成型方式 | 优点 | 缺点 | |

|---|---|---|---|---|

| 模压成型 | 通过施加压力将粉末材料压制成型 | 操作简单,陶瓷致密度较高,性能稳定 | 脱模困难,易损伤坯体,难以形成复杂结构 | |

| 注射成型 | 陶瓷粉末与有机粘结剂混合形成浆料,注入模具内成型 | 适合较复杂形状零件的生产,精度高 | 形状复杂性有限,依赖于模具,材料损耗较大 | |

| 挤出成型 | 加压将陶瓷浆料挤出模具而成型 | 生产效率高,较好的尺寸稳定性 | 形状复杂性有限,挤出过程中易产生缺陷,影响坯体的致密性 | |

| 光固化3D打印成型 | 数字光处理(DLP) | 使用数字投影仪使光敏树脂逐层曝光固化 | 无模具限制,成型速度快,材料表面光滑 | 材料选择有限,尺寸限制,需要后处理 |

| 立体光刻(SLA) | 激光逐点扫描光敏树脂,逐层固化 | 无模具限制,精度高,成型速度快,材料表面光滑 | 设备成本高,材料选择有限,需要后处理 | |

| 双光子聚合(TPP) | 利用超快激光在三维空间内引发光敏聚合物的聚合反应 | 无模具限制,极高的分辨率,适合微纳米结构制造 | 设备成本高,材料选择有限 | |

| 熔融沉积 | 加热熔化材料,由喷嘴挤出并逐层沉积 | 材料多样,成本低,操作简单 | 精度较低,各向异性强 | |

| 直写成型 | 通过喷嘴挤出浆料或膏体,并在沉积后固化 | 多材料兼容,适合制备复杂的几何形状,材料使用效率高 | 分辨率有限,后处理复杂,速度较慢 | |

| 选择性激光烧结 | 通过激光逐层烧结粉末材料形成三维物体 | 材料多样,无需支撑结构,陶瓷力学性能好 | 材料表面粗糙,需要后处理,成本高 | |

| 粘结剂喷射成型 | 喷射粘结剂至粉末床,逐层粘结粉末而成型 | 速度快,适合多材料打印,成本低 | 材料强度低,精度低,后处理复杂 | |

氮化硅陶瓷传统成型工艺主要包括模压成型和注射成型,如图1所示。其中,模压成型的基本原理见图1(a)[

22

23

模压成型主要分为干压成型和冷等静压成型两种方式。其中,干压成型通过对模具施加压力,使氮化硅颗粒紧密接触形成致密坯体。该成型工艺以简单高效的特点而被广泛应用于中小型简单结构陶瓷件的生产。然而,尽管该工艺可以形成均匀的坯体,但常因颗粒间接触不够牢固而导致结构缺失,影响最终成型效果。

冷等静压成型是一种高效制备氮化硅陶瓷的方法,在该工艺中,首先将氮化硅颗粒与适量烧结助剂(如Y2O3和MgO)混合,然后将混合后的粉体装入柔性模具中,通过液体介质(如油或水)施加均匀的静态压力(通常为200~400 MPa),均匀的压力分布能够有效消除颗粒之间的空隙,确保坯体均匀致密。Wang等[

24

25

26

通常,模压成型和烧结工艺之间密不可分,将模压成型与烧结工艺进行结合,通过加热加压的方式获得高密度和力学性能优异的氮化硅陶瓷。Poorteman等[

27

28

注射成型是将氮化硅颗粒与适量的粘结剂(如聚合物)混合形成均匀浆料,然后在加热和加压条件下将浆料注入模具内,待冷却后去除模具,从而形成所需形状的氮化硅陶瓷素坯,其原理如图1(b)所示。该方法对注射浆料的流动性和黏度要求较高,若控制不当,可能产生气泡,最终导致成型缺陷。此外,该工艺在很大程度上受模具影响,模具的设计直接决定了氮化硅陶瓷的形状结构。

为提高氮化硅陶瓷注射成型的效果,可以考虑以下几种改进方法:首先,优化浆料成分,通过调整粒径和聚合物比例改善氮化硅陶瓷浆料的流动性,从而提高素坯的成型效果[

崔凯, 张永翠, 宋涛, 等. 不同参数对注射成型异形结构陶瓷的影响[J]. 山东陶瓷, 2022, 45(5): 65–70.CUI Kai, ZHANG Yongcui, SONG Tao, et al. Influence of different parameters on injection-molded heteroideus-shaped structural ceramics[J]. Shandong Ceramics, 2022, 45(5): 65–70.

29-30

31

32

33

34

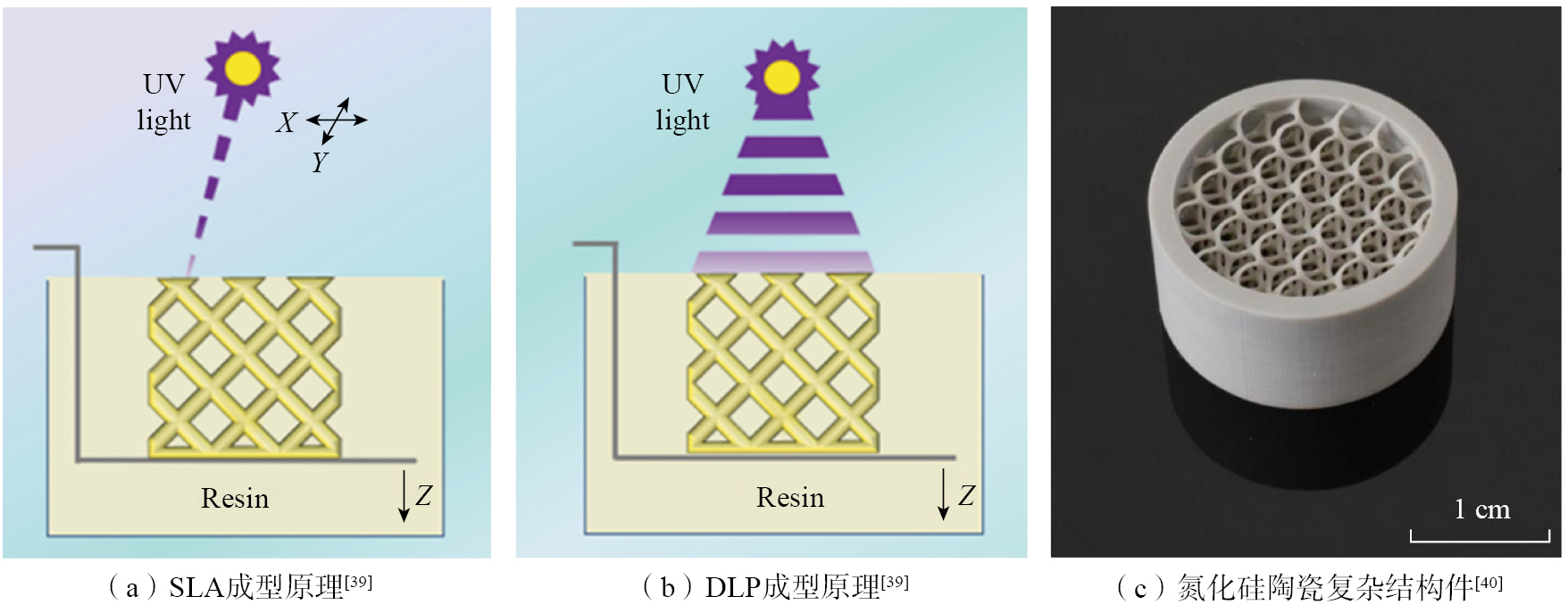

增材制造技术为氮化硅陶瓷的成型提供了一种全新的技术方案[

DONG X J, WU J Q, YU H L, et al. Additive manufacturing of silicon nitride ceramics: A review of advances and perspectives[J]. International Journal of Applied Ceramic Technology, 2022, 19(6): 2929–2949.

CRAMER C L, IONESCU E, GRACZYK-ZAJAC M, et al. Additive manufacturing of ceramic materials for energy applications: Road map and opportunities[J]. Journal of the European Ceramic Society, 2022, 42(7): 3049–3088.

35-37

38

39

40

41

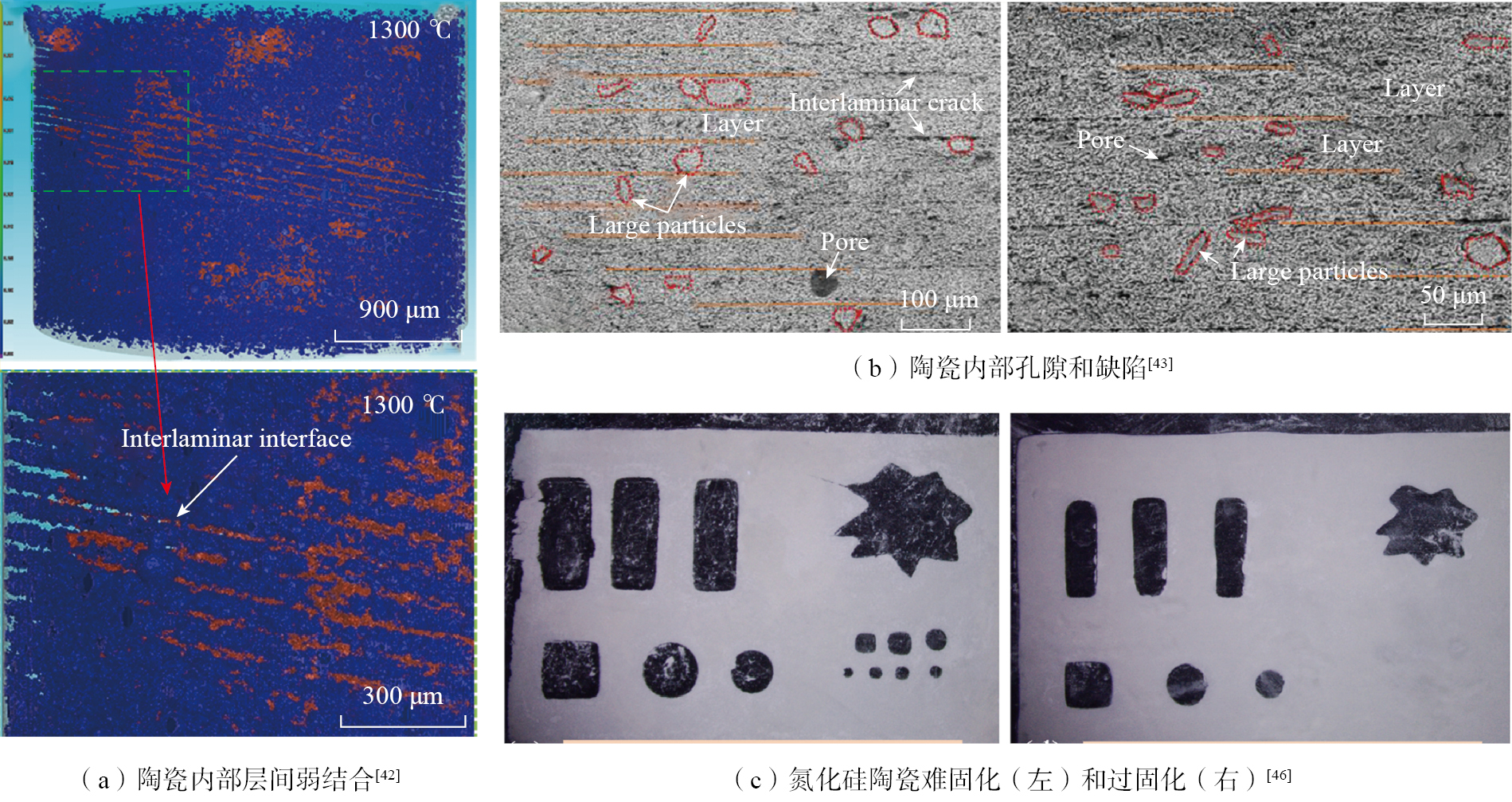

光固化增材制造通过数字化设计和直接打印减少了传统制造工艺中的模具限制和后续加工步骤,使设计理念更快速地转化为实际产品,这种生产灵活性对于满足航空航天领域复杂结构件的需求具有重要意义。然而,光固化增材制造在制备氮化硅陶瓷时也面临一些明显的弊端,例如3D打印本身的堆积特性使陶瓷材料层间结合弱(图3(a)[

42

43

LUTHER E E, LANGE F F, PEARSON D S. “Alumina” surface modification of silicon nitride for colloidal processing[J]. Journal of the American Ceramic Society, 1995, 78(8): 2009–2014.

44-45

46

47

38

48

49

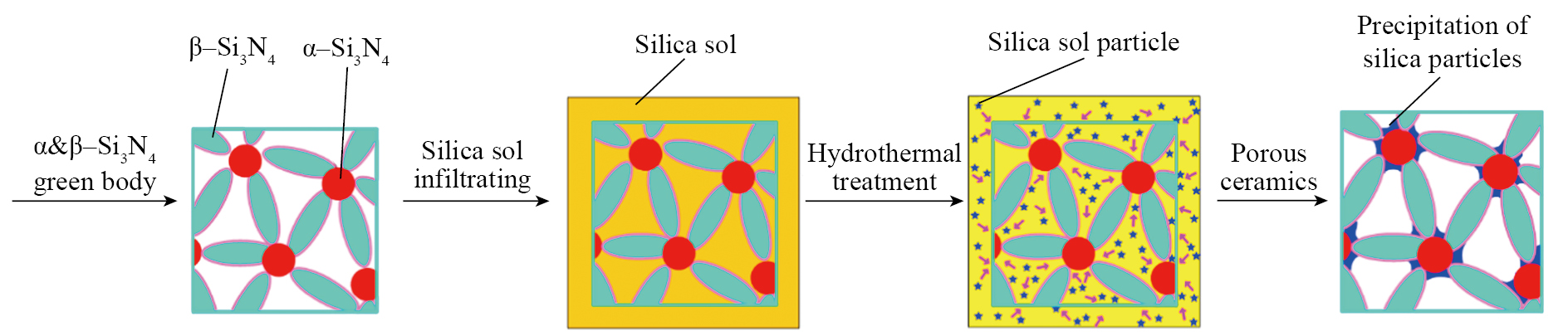

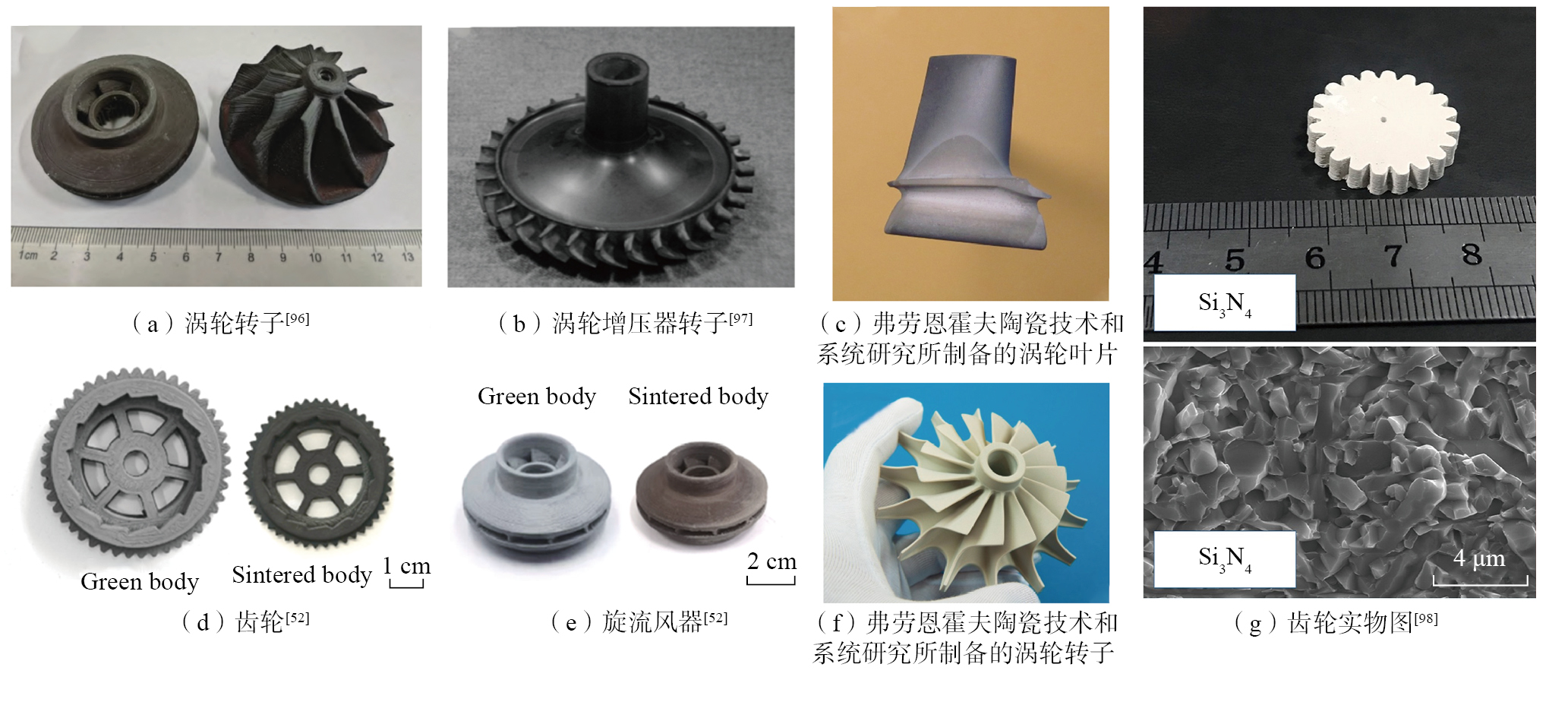

除上述几种主流的陶瓷成型工艺外,氮化硅陶瓷制备还包括凝胶注模成型、挤出成型、熔融沉积成型、水凝胶悬浮挤压等工艺。不同的生产工艺各有利弊,但都为氮化硅陶瓷的成型提供了可行的途径。Hu等[

50

50

50

Yang等[

51

20

52

随着成型技术的不断发展,特别是增材制造技术的引入,氮化硅陶瓷在航空航天领域的应用潜力显著提升。传统成型方法与增材制造技术的结合,使得氮化硅陶瓷不仅能满足所需的性能要求,还能实现复杂结构的制备。未来,这些成型工艺将为氮化硅陶瓷在航空航天领域的应用带来更多创新和可能。

在航空航天领域服役过程中,氮化硅陶瓷通常面临高温高压、冷热循环、高冲刷等极端环境,其性能直接影响服役过程中的稳定性和可靠性,性能优异的氮化硅陶瓷对航空航天领域的发展具有重要意义。

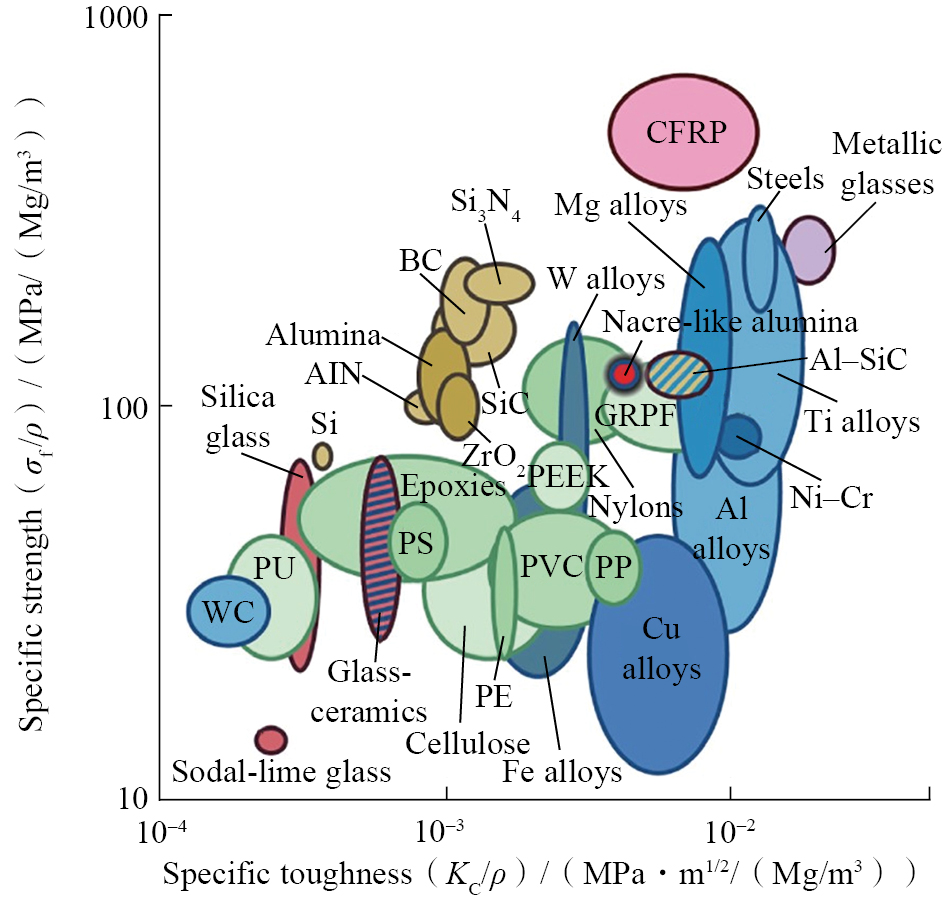

Bouville等[

53

53

53

目前,国内外对氮化硅陶瓷的性能检测主要集中在常温、常压和瞬时条件(工况)下,常通过硬度[

JIANG J Z, KRAGH F, FROST D J, et al. Hardness and thermal stability of cubic silicon nitride[J]. Journal of Physics: Condensed Matter, 2001, 13(22): L515–L520.

54-55

56

57

58

59

60

61

62

63

64

65

基于上述总结和相关文献,对氮化硅陶瓷在室温下的强度和韧性进行统计,如表2所示[

6

28

YIN S, JIANG S C, PAN L M, et al. Preparation, mechanical and thermal properties of Si3N4 ceramics by gelcasting using low-toxic DMAA gelling system and gas pressure sintering[J]. Ceramics International, 2018, 44(18): 22412–22420.

61-62

WANG L, WANG L Y, HAO Z D, et al. Microstructure and properties of silicon nitride ceramics fabricated by vat photopolymerization in combination with pressureless sintering[J]. Ceramics International, 2024, 50(7): 10485–10496.

李成卓, 邓腾飞. 氧化铁对氮化硅陶瓷烧结的影响[J]. 陶瓷学报, 2024, 45(3): 558–565.LI Chengzhuo, DENG Tengfei. Effect of iron oxide on sintering behavior of silicon nitride ceramics[J]. Journal of Ceramics, 2024, 45(3): 558–565.

ZHANG Q, WANG W L, ZHANG Z X, et al. Enhancing fracture toughness of silicon nitride ceramics by addition of β–Si3N4 whisker and MXene[J]. Ceramics International, 2024, 50(19): 35695–35705.

FU Q L, FU J X, WANG J, et al. Defects control of silicon nitride ceramics by oscillatory pressure sintering and consequent hot isotropic pressing[J]. Ceramics International, 2024, 50(2): 3276–3280.

YE C C, YUE X Y, JIANG Y, et al. Effect of different preparation methods on the microstructure and mechanical properties of Si3N4 ceramic composites[J]. Ceramics International, 2018, 44(4): 3664–3671.

YIN S, PAN L M, LIU Y, et al. Effect of β–Si3N4 seeds on microstructure and properties of porous Si3N4 ceramics prepared by gelcasting using DMAA system[J]. Ceramics International, 2020, 46(4): 4924–4932.

YU J J, WEI W X, GUO W M, et al. Enhanced mechanical properties of Si3N4 ceramics with ZrB2–B binary additives prepared at low temperature[J]. Journal of the European Ceramic Society, 2019, 39(15): 5102–5105.

RATZKER B, SOKOL M, KALABUKHOV S, et al. High-pressure spark plasma sintering of silicon nitride with LiF additive[J]. Journal of the European Ceramic Society, 2018, 38(4): 1271–1277.

LEE S H. Densification, mass loss, and mechanical properties of low-temperature pressureless-sintered Si3N4 with LiYO2 additive: The effects of additive content and annealing[J]. International Journal of Applied Ceramic Technology, 2010, 7(6): 881–888.

ZHUANG Y H, SUN F, ZHOU L J, et al. The influence of magnesium compounds on the properties of silicon nitride ceramics[J]. International Journal of Applied Ceramic Technology, 2024, 21(3): 2273–2287.

HU Y Y, CHEN Z Q, ZHANG J J, et al. Preparation and mechanical properties of Si3N4 nanocomposites reinforced by Si3N4@rGO particles[J]. Journal of the American Ceramic Society, 2019, 102(11): 6991–7002.

MENG Q Y, ZHAO Z H, SUN Y Q, et al. Low temperature pressureless sintering of dense silicon nitride using BaO–Al2O3–SiO2 glass as sintering aid[J]. Ceramics International, 2017, 43(13): 10123–10129.

DUAN Y S, ZHANG J X, LI X G, et al. Low temperature pressureless sintering of silicon nitride ceramics for circuit substrates in powder electronic devices[J]. Ceramics International, 2018, 44(4): 4375–4380.

KITAYAMA M, HIRAO K, TORIYAMA M, et al. High Hardness α–Si3N4 ceramics reinforced by rod-like β–Si3N4 seed particles[J]. Journal of the Ceramic Society of Japan, 2000, 108(1259): 646–649.

64-78

| 氮化硅陶瓷成分 | 硬度/GPa | 弯曲强度/MPa | 断裂韧性/(MPa·m1/2) | 文献 |

|---|---|---|---|---|

| α–Si3N4、Y2O3、MgO、WC、GdF3 | 16.23 | 710 | 7.8 | [ 64 |

| α–Si3N4、Al2O3、MgF2、ZrO2、Fe2O3 | 13.34 | 360 | 2.4 | [ 66 |

| Si3N4、Al2O3、Y2O3 | 12.6 | 613 | 7.5 | [ 65 |

| Si3N4、β–Si3N4晶须、Al2O3、Y2O3、CaF2、Ta3C4Tx | 16.5 | 743 | 9.7 | [ 67 |

| α–Si3N4、Al2O3、Y2O3 | — | 1630 | 7.1 | [ 68 |

| α–Si3N4、Al2O3、Y2O3 | 19 | 800 | 6.0 | [ 78 |

| α–Si3N4、Al2O3、Y2O3 | 16.31 | 817 | 6.9 | [ 69 |

| α–Si3N4、Al2O3、Y2O3、Al(NO3)3·9H2O、Y(NO3)3·6H2O | 16.23 | 911 | 4.9 | [ 28 |

| α–Si3N4、β–Si3N4、Y2O3、Al2O3 | — | 378 | 8.6 | [ 70 |

| α–Si3N4、MgO、Yb2O3、ZrB2、B | 17 | 675 | 7.2 | [ 71 |

| α–Si3N4、Y2O3、Al2O3、LiF | 17.3 | 1720 | 6.0 | [ 72 |

| Si3N4、Y2O3、Li2CO3、LiYO2 | 13.9 | 640 | 5.5 | [ 73 |

| α–Si3N4、Er2O3、MgO、MgF2、Mg2Si、Mg3N2 | 16.8 | 912 | 8.1 | [ 74 |

| β–Si3N4 | 17.3 | 1116 | 10.4 | [ 75 |

| α–Si3N4、BaCO3、Al2O3、SiO2 | 12.23 | 373 | 4.8 | [ 76 |

| Si3N4、TiO2、MgO | 14 | 668 | 5.1 | [ 77 |

| α–Si3N4、Y2O3、Al2O3 | — | 770 | 13.3 | [ 6 |

| Si3N4 | 2.18 | 898 | 6.4 | [ 62 |

| α–Si3N4、MgO、LiF | 9.07 | 556 | 6.0 | [ 61 |

传统的室温性能检测方法难以真实反映氮化硅陶瓷在航空航天等极端服役环境下的实际表现。为了确保氮化硅结构件在高温复杂工况中能够稳定运行,亟须发展能够模拟真实服役条件的高温性能测试手段。然而,由于氮化硅陶瓷具有极高的使用温度和强度,目前的传统检测设备难以在超高温条件下稳定工作,导致材料在高温服役过程中的性能变化难以被准确评估。

针对氮化硅陶瓷在高温检测中面临的诸多技术挑战,国内外已开展了一系列探索,致力于研发更先进的高温测试设备,以提高设备在极端条件下的测试精度及准确性。例如,瑞典KANTHAL公司研发的二硅化钼加热元件(Kanthal Super1900)能够在短时间内达到1850 ℃的极限温度,配备该发热源后,力学性能试验机在1700 ℃下可完成拉伸、压缩、弯曲及持久蠕变等多种力学性能试验。德国NETZSCH和美国TA Instruments等公司研发的激光导热仪和高温力学测试仪器,为科研人员提供了高精度的检测手段。这些设备采用非接触测量技术(如激光闪射法和高温原位测试),能够在1600 ℃以上的高温条件下评估氮化硅陶瓷的导热性和力学性能。此外,国内在高温检测设备的研发方面也在持续推进,许多高校和科研机构围绕氮化硅陶瓷的高温性能展开了专门研究。例如,中国科学院金属研究所将非接触式温度传感器与高温负载测试装置结合,成功组装了高温力学性能试验机,该设备可完成1600 ℃以内的力学性能检测,并能实时监测温度,可准确地反映氮化硅陶瓷在高温环境下的真实性能;三思泰捷与清华大学、中国科学院力学研究所合作开发了超高温拉伸机,配置了碳化硅高温炉和重结晶碳化硅高温夹具,可满足1400 ℃的超高温试验条件。

随着对高温结构材料需求的不断增加,氮化硅陶瓷的性能不再局限于常温条件下的优化,该材料在高温环境中的表现更为重要,因此高温力学性能检测将成为未来氮化硅陶瓷性能研究的重点方向。这一领域的突破对于促进氮化硅陶瓷在航空航天领域的工程化应用至关重要。

氮化硅陶瓷在极端环境下的可靠性是近年来需要解决的主要问题,为了满足该材料在航空航天领域的服役要求,性能调控已成为氮化硅陶瓷研究的关键。国内外学者主要从微结构调控和第二相增韧补强两方面提升氮化硅陶瓷性能。

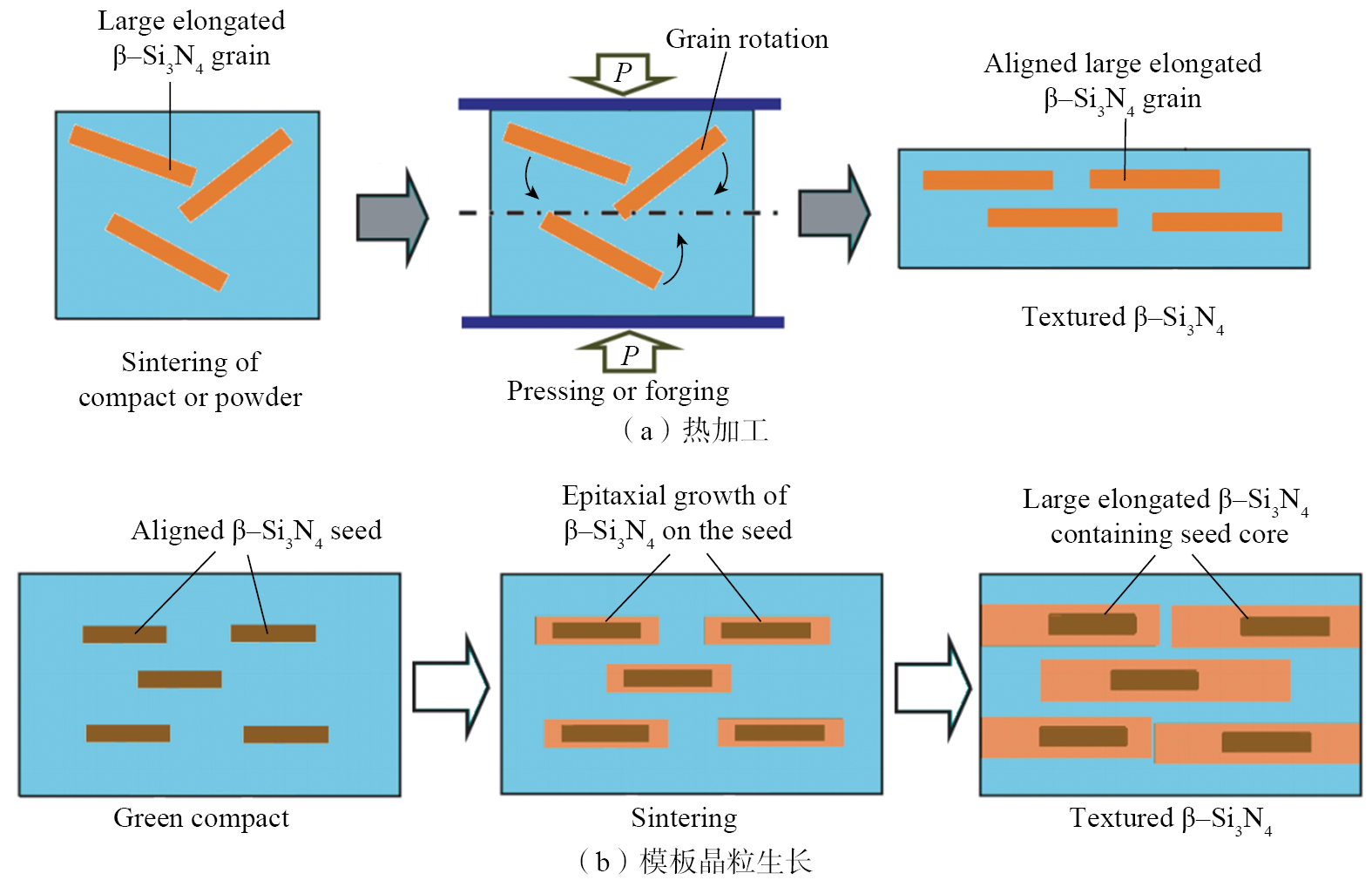

研究表明,通过调控微观组织结构可以显著提升氮化硅陶瓷的力学性能[

ZHU X W, SAKKA Y. Textured silicon nitride: Processing and anisotropic properties[J]. Science and Technology of Advanced Materials, 2008, 9(3): 033001.

LEE F, BOWMAN K J. Texture and anisotropy in silicon nitride[J]. Journal of the American Ceramic Society, 1992, 75(7): 1748–1755.

TAN D W, GUO W M, LAO Z Y, et al. A novel strategy for c-axis textured silicon nitride ceramics by hot extrusion[J]. Journal of the European Ceramic Society, 2021, 41(12): 6059–6063.

TANG S J, LI Z H, GUO W M, et al. Fabrication of one-dimensional textured Si3N4-based ceramics with high hardness and toughness by low temperature hot extrusion[J]. Ceramics International, 2024, 50(21): 41975–41981.

79-83

79

80

81

82

83

80

80

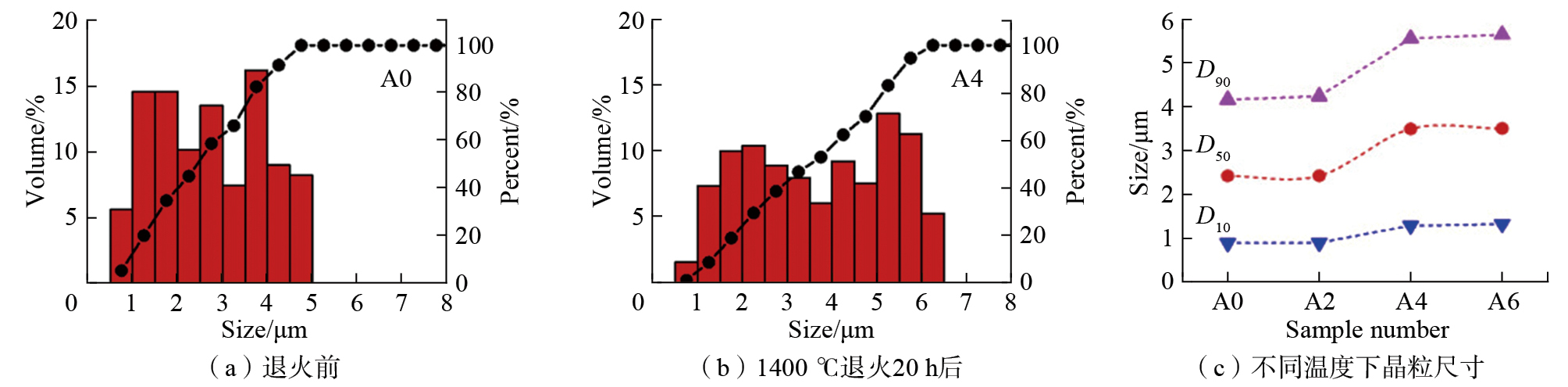

除织构化外,控制颗粒级配同样可以调节氮化硅陶瓷的微观组织,提高其性能。Lv等[

84

85

适宜的烧结工艺不仅能够促进陶瓷颗粒间的融合,优化组织结构,还能消除成型过程中产生的内应力,提升材料的强度、韧性和导热性[

86

87

68

88

89

88

88

Zhang等[

90

90

90

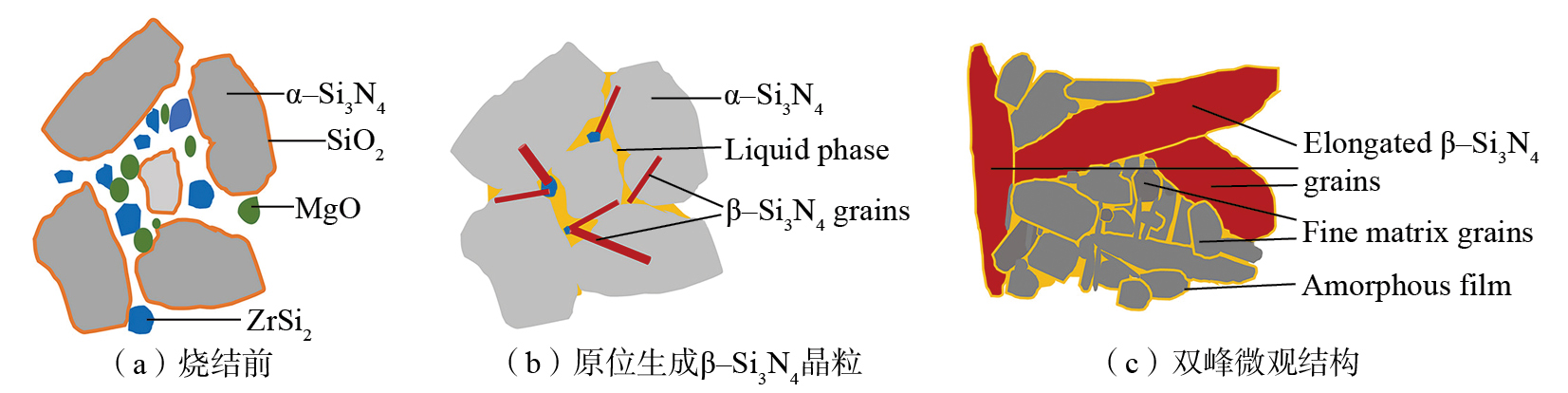

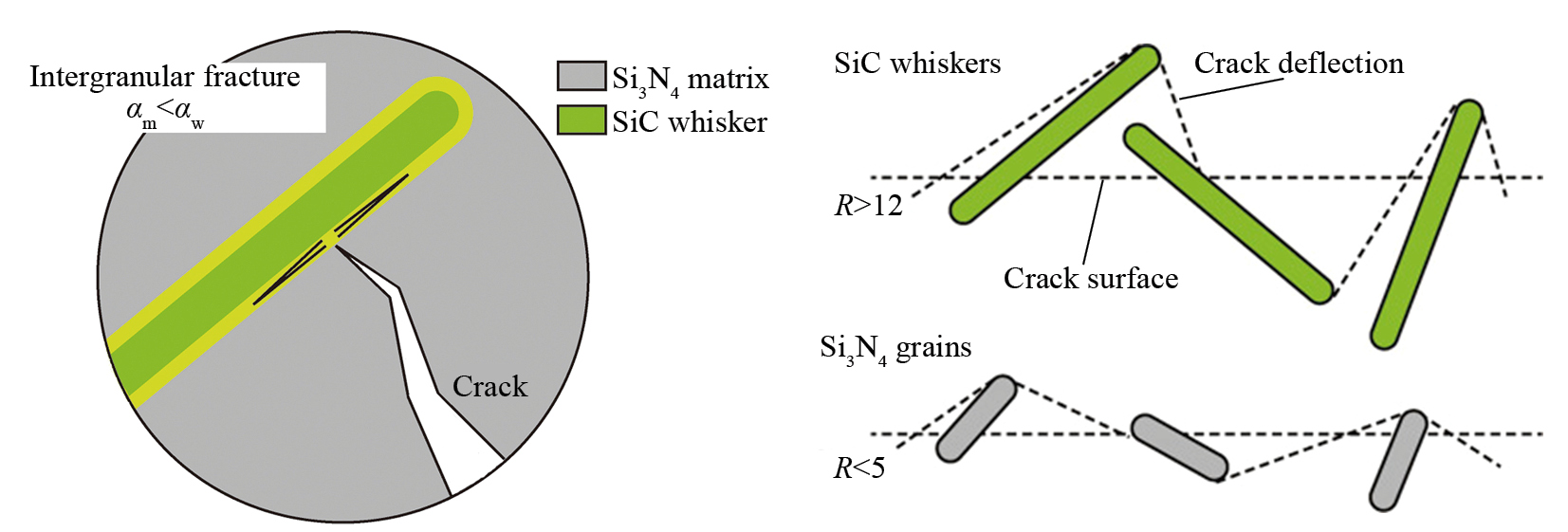

氮化硅陶瓷的增韧补强方法主要包括自增韧和第二相增韧。其中,自增韧是氮化硅陶瓷的重要性能之一,主要通过烧结过程中氮化硅陶瓷的α相向β相转化,形成延伸的β–Si3N4晶粒,如图10所示[

24

91

24

24

在氮化硅基体中引入第二相颗粒或晶须,同样可以有效提高氮化硅陶瓷的力学性能。该方法的增韧机制主要通过以下两方面实现:(1)第二相在裂纹扩展路径上形成阻碍,导致裂纹偏转,从而增加裂纹扩展所需的能量;(2)第二相能够吸收裂纹扩展过程中释放的能量,减缓裂纹传播速度,进而提高材料的抗断裂能力。

适当选择或添加增韧颗粒是提升陶瓷力学性能的关键。李成卓等[

66

92

74

93

94

95

95

95

综上所述,氮化硅陶瓷在性能调控方面已取得显著进展,这些方法的综合应用有效提升了氮化硅陶瓷在复杂环境中的应用可靠性。但随着航空航天领域的不断发展,未来的研究应聚焦于材料性能的持续优化,以应对更为严苛的工作环境和服役需求。

近年来,许多研究开始探索利用氮化硅陶瓷制备发动机叶片、尾喷管等航空航天结构件(图12[

52

HAMPSHIRE S. Silicon nitride ceramics—Review of structure, processing and properties[J]. Journal of Achievements in Materials and Manufacturing Engineering, 2007, 24(1): 43–50.

LIN L F, WU H D, HUANG Z Q, et al. Effect of monomers with different functionalities on stability, rheology, and curing behavior of ceramic suspensions[J]. Materials Chemistry and Physics, 2022, 275: 125243.

96-98

氮化硅陶瓷被认为是超声速飞行器天线罩、导弹精确制导天线罩和传感器保护壳的首选波传输材料[

99

100

101

由于氮化硅陶瓷能够承受高温、高压和高速气流冲击,目前已成为涡轮增压器转子和燃气涡轮发动机部件的主要候选材料[

102

随着航空航天领域的不断发展,氮化硅陶瓷在轻量化、高温承载和复杂结构件方面的需求日益增加,展现出广阔的应用前景。未来,在增材制造等先进技术的推动下,氮化硅陶瓷能够更好地满足复杂结构件的制备需求,在高温防护、精密结构件和耐热传感器等领域发挥重要作用。

本文全面总结了氮化硅陶瓷在成型、检测方法、性能调控等方面的研究现状,明确了氮化硅陶瓷在航空航天领域的应用及潜力。然而,随着航空航天领域对材料性能、结构要求的不断提升,氮化硅陶瓷在长期使用中的可靠性和耐久性仍需进一步验证,特别是在极端环境下,其性能稳定性和使用寿命是需要关注的重点问题。为推动氮化硅陶瓷在航空航天领域的快速发展,本文结合当前研究现状提出3点建议,具体如下。

(1)氮化硅陶瓷的高温性能检测尚未形成完整规范。现阶段,超高温检测设备及技术不够成熟,亟须进一步完善。现有的检测方法多集中于室温条件,导致研究人员对氮化硅陶瓷在极端环境中的行为和性能认识不足。因此,未来亟须开发更为先进的高温检测设备、检测手段,规范极端环境下的检测标准,以便更全面地评价氮化硅陶瓷的真实性能。

(2)氮化硅陶瓷在极端环境下的可靠性有待提升。氮化硅陶瓷虽然表现出一定的韧性,但韧性不足仍然是制约该材料在航空航天领域长期服役和广泛应用的关键阻碍。因此,未来氮化硅陶瓷仍需在性能提升方面继续改进。通过引入韧性更高的第二相、优化微观结构设计及改进烧结工艺等方法,进一步提升氮化硅陶瓷的综合性能。

(3)进一步发展氮化硅陶瓷增材制造成型工艺。复杂结构成型是制约氮化硅陶瓷实际应用的关键因素,与传统成型工艺相比,增材制造技术提供了更高的设计灵活性。其中,光固化成型工艺不仅能够实现复杂结构的快速成型,而且在精度和成本方面具有其他增材制造技术无法比拟的独特优势。通过深入研究光固化增材制造技术,氮化硅陶瓷有望在结构和性能优化方面取得显著进展。未来,氮化硅陶瓷的光固化增材制造技术必将成为航空航天领域发展的重要方向之一。

参考文献

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] | |

| [35] | |

| [36] | |

| [37] | |

| [38] | |

| [39] | |

| [40] | |

| [41] | |

| [42] | |

| [43] | |

| [44] | |

| [45] | |

| [46] | |

| [47] | |

| [48] | |

| [49] | |

| [50] | |

| [51] | |

| [52] | |

| [53] | |

| [54] | |

| [55] | |

| [56] | |

| [57] | |

| [58] | |

| [59] | |

| [60] | |

| [61] | |

| [62] | |

| [63] | |

| [64] | |

| [65] | |

| [66] | |

| [67] | |

| [68] | |

| [69] | |

| [70] | |

| [71] | |

| [72] | |

| [73] | |

| [74] | |

| [75] | |

| [76] | |

| [77] | |

| [78] | |

| [79] | |

| [80] | |

| [81] | |

| [82] | |

| [83] | |

| [84] | |

| [85] | |

| [86] | |

| [87] | |

| [88] | |

| [89] | |

| [90] | |

| [91] | |

| [92] | |

| [93] | |

| [94] | |

| [95] | |

| [96] | |

| [97] | |

| [98] | |

| [99] | |

| [100] | |

| [101] | |

| [102] | |