铝合金激光–电弧复合焊接技术的研究进展

通信作者:

高义皓,硕士研究生,研究方向为多能场复合焊接。

基金项目:

国家自然科学基金(52305362)。

中图分类号:

V26

文献标识码:

A

引用格式

陈超, 高义皓, 任柏桥, 等. 铝合金激光–电弧复合焊接技术的研究进展[J]. 航空制造技术, 2025, 68(9): 47–60.

摘要

铝合金因其优异的轻质、高强度和耐腐蚀等性能,在航空航天、汽车制造等领域得到了广泛应用。然而,铝合金的焊接一直是制造领域中的一个难题,传统焊接方法存在热输入大、变形严重等问题。近年来,激光–电弧复合焊接技术因结合了激光焊接与电弧焊接的优势,成为解决铝合金焊接难题的重要手段。本文系统综述了激光–电弧复合焊接在铝合金领域的研究进展,介绍了激光–电弧复合焊接的协同作用原理与技术优势,对焊接组织与力学性能及其影响因素进行分析,针对复合焊接接头目前存在的一系列问题总结了解决方法,并展望了该技术的未来发展方向及在工业领域的应用前景。

关键词

铝合金;激光–电弧复合焊接;焊接工艺;接头性能;工业应用;

Research Progress of Laser–Arc Hybrid Welding Technology for Aluminum Alloy

Citations

CHEN Chao, GAO Yihao, REN Boqiao, et al. Research progress of laser–arc hybrid welding technology for aluminum alloy[J]. Aeronautical Manufacturing Technology, 2025, 68(9): 47–60.

Abstract

Aluminum alloys are widely used in areas of aerospace, automobile manufacturing, etc., due to their low density, high strength and corrosion resistance. However, the welding of aluminum alloys is a challenge in manufacturing fields, in which, traditional welding methods have problems such as high heat input and serious deformation. In recent years, laser–arc hybrid welding technology, which combines the advantages of laser welding and arc welding, has become an important method to solve the problems existed in aluminum alloy welding. This paper systematically reviews the research progress of laser–arc hybrid welding for aluminum alloys. Synergistic mechanism and technology advantages of laser–arc hybrid welding are introduced; welding structure and mechanical properties and their influencing factors are analyzed; solutions to a series of problems existed in hybrid welding joint are summarized. Finally, the development directions and application prospects of the laser–arc hybrid welding technology are expected, including automatic and intelligent development, new protective gas and welding filling materials and novel applications of laser–arc hybrid welding technology.

Keywords

Aluminum alloy

铝合金因其密度低、比强度高及优异的高温性能等优点,被广泛应用于航空航天、交通运输等领域[

CHEN K, XIAO R S, ZUO T C, et al. Laser welding of Al–Mg alloy with the thin plate[C]//Lasers in Material Processing and Manufacturing II. Beijing: SPIE, 2005: 155.

洪蕾, 吴钢, 陈武柱. 保护气流对CO2激光焊接铝合金的影响[J]. 中国激光, 2005, 32(11): 1571-1576.HONG Lei, WU Gang, CHEN Wuzhu. Influence of shielding gas flow on welding quality for CO2 laser welding of aluminum alloy[J]. Chinese Journal of Lasers, 2005, 32(11): 1571-1576.

1-3

4

5

林文超. 汽车铝合金车身焊接工艺开发与应用分析[J]. 时代汽车, 2023(15): 132-134.LIN Wenchao. Development and application analysis of automotive aluminum alloy body welding process[J]. Auto Time, 2023(15): 132-134.

金聪聪, 黄立兵, 黄文彬, 等. 新型铝合金MIG焊接头微观组织与力学性能[J]. 焊接学报, 2024, 45(7): 74-82.JIN Congcong, HUANG Libing, HUANG Wenbin, et al. Microstructure and mechanical properties of new aluminum alloy MIG welded joint[J]. Transactions of the China Welding Institution, 2024, 45(7): 74-82.

6-8

ION J C. Laser beam welding of wrought aluminium alloys[J]. Science and Technology of Welding and Joining, 2000, 5(5): 265-276.

MAHRLE A, BEYER E. Hybrid laser beam welding—Classification, characteristics, and applications[J]. Journal of Laser Applications, 2006, 18(3): 169-180.

9-11

12

KATAYAMA S, KAWAGUCHI S, MIZUTANI M, et al. Welding phenomena and in-process monitoring in high-power YAG laser welding of aluminium alloy[J]. Welding International, 2009, 23(10): 753-762.

13-14

15

MAZAR ATABAKI M, NIKODINOVSKI M, CHENIER P, et al. Experimental and numerical investigations of hybrid laser arc welding of aluminum alloys in the thick T-joint configuration[J]. Optics & Laser Technology, 2014, 59: 68-92.

16-17

本文系统介绍激光–电弧复合焊接的原理与协同机理,以及复合焊接技术的工艺优势,概括了工艺参数对焊缝质量的影响;对复合焊接接头的显微组织、综合性能进行分析,讨论了接头缺陷的产生机理及解决途径,并针对铝合金厚板复合焊接中的一系列挑战提供了解决方法;总结概括了激光–电弧复合焊接技术在航空航天、汽车制造、船舶及电力设备等领域的应用;最后展望了复合焊接技术未来的发展方向。

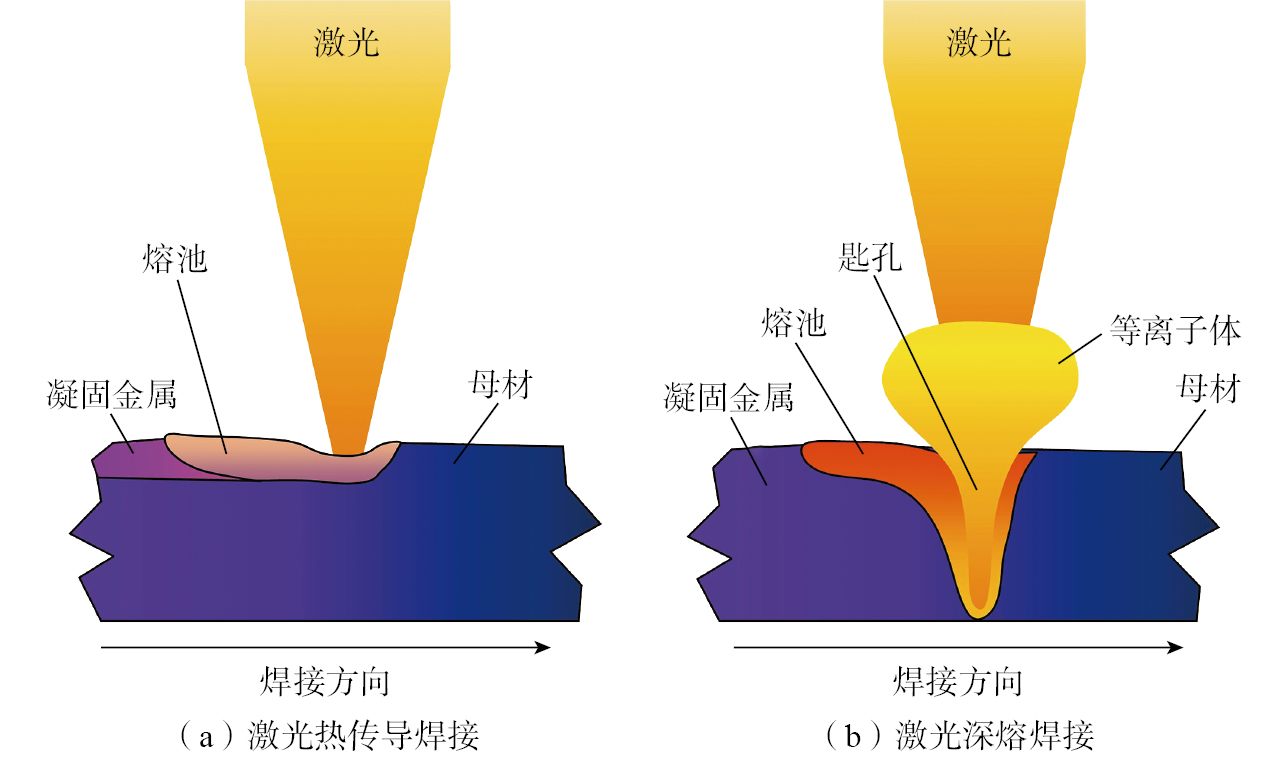

激光焊接技术是指利用激光束热能将工件加热至熔化或汽化状态,通过固化形成焊缝的一种焊接方法,根据焊接方法的不同可分为激光热传导焊接和激光深熔焊接,如图1所示[

18

徐同乐. 现代激光技术在航空机械加工中的应用实践[J]. 中国机械, 2023(5): 68-71.XU Tongle. Application practice of modern laser technology in aerospace machining[J]. Machine China, 2023(5): 68-71.

18-19

20

18

18

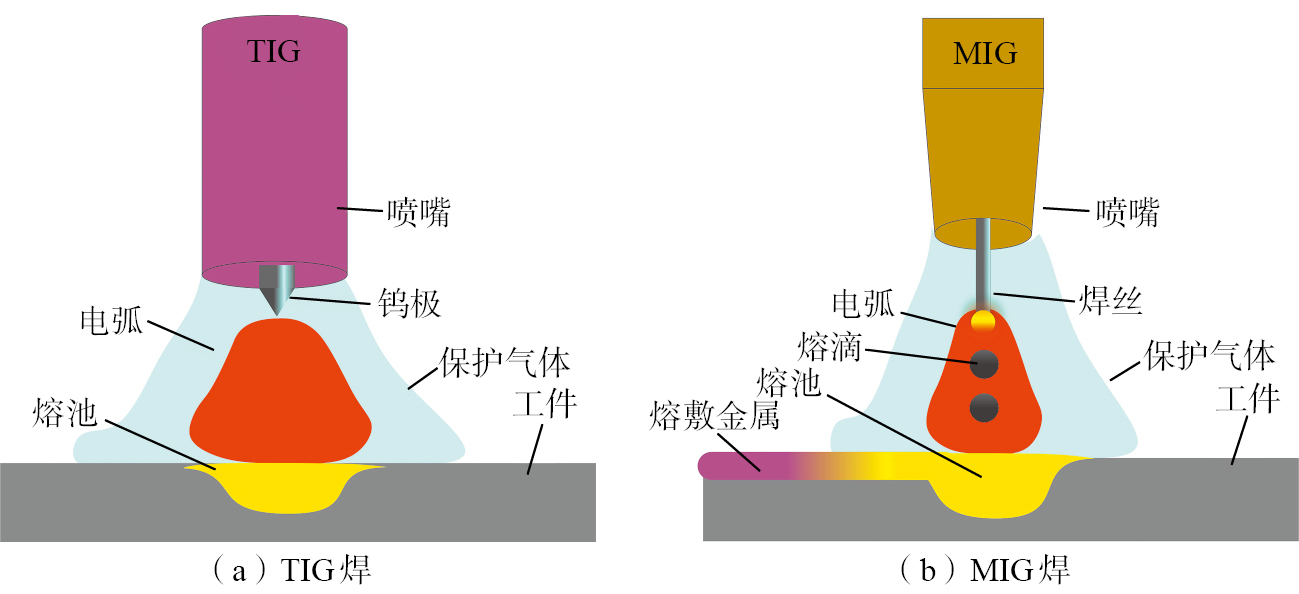

电弧焊接的基本原理是利用电流通过焊条和工件之间的空气间隙产生电离现象,形成稳定的电弧,将待焊工件或填充焊丝熔化后再凝固,达到物体连接的目的[

21

22

22

22

22

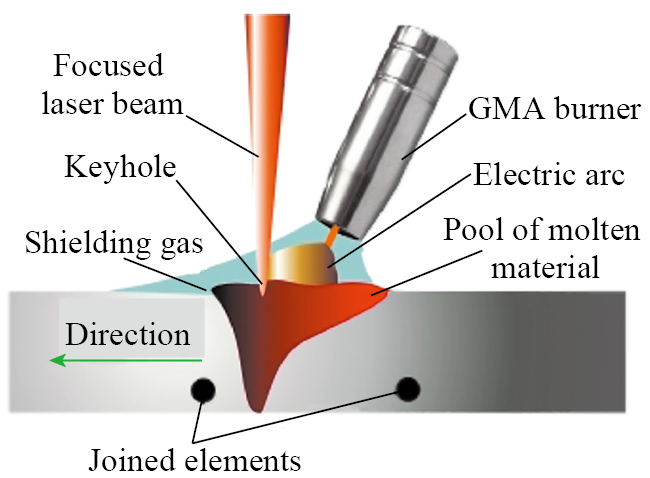

在激光–电弧复合焊接过程中,激光束和电弧作为两种热源同时加热母材,使之熔化并产生熔池,由于铝合金液态熔池的反射率低于固态金属,此时激光束能够直接辐射到液态熔池表面从而提高激光能量的利用率[

ACHERJEE B. Hybrid laser arc welding: State-of-art review[J]. Optics & Laser Technology, 2018, 99: 60-71.

23-24

24

HU B, DEN OUDEN G. Laser induced stabilisation of the welding arc[J]. Science and Technology of Welding and Joining, 2005, 10(1): 76-81.

FUJINAGA S, OHASHI R, KATAYAMA S, et al. Improvements of welding characteristics of aluminum alloys with YAG laser and TIG arc hybrid system[C]//First International Symposium on High-Power Laser Macroprocessing. Osaka: SPIE, 2003: 301.

TIX C, GRATZKE U, SIMON G. Absorption of the laser beam by the plasma in deep laser beam welding of metals[J]. Journal of Applied Physics, 1995, 78(11): 6448-6453.

BIBIK O, BRODYAQIN V, ROKLADOV Y. Special features of interaction of laser radiation with the electric welding arc in the combined laser–arc welding[J]. Physics and Chemistry of Materials Treatment, 1990, 24(2): 176-178.

25-29

24

24

激光–电弧复合热源并不是激光和电弧两种热源简单叠加的过程,而是将两种热源的优势融合到一起,从而弥补两种热源不足的高效复合热源[

30

31

32

33

34

35

36

37

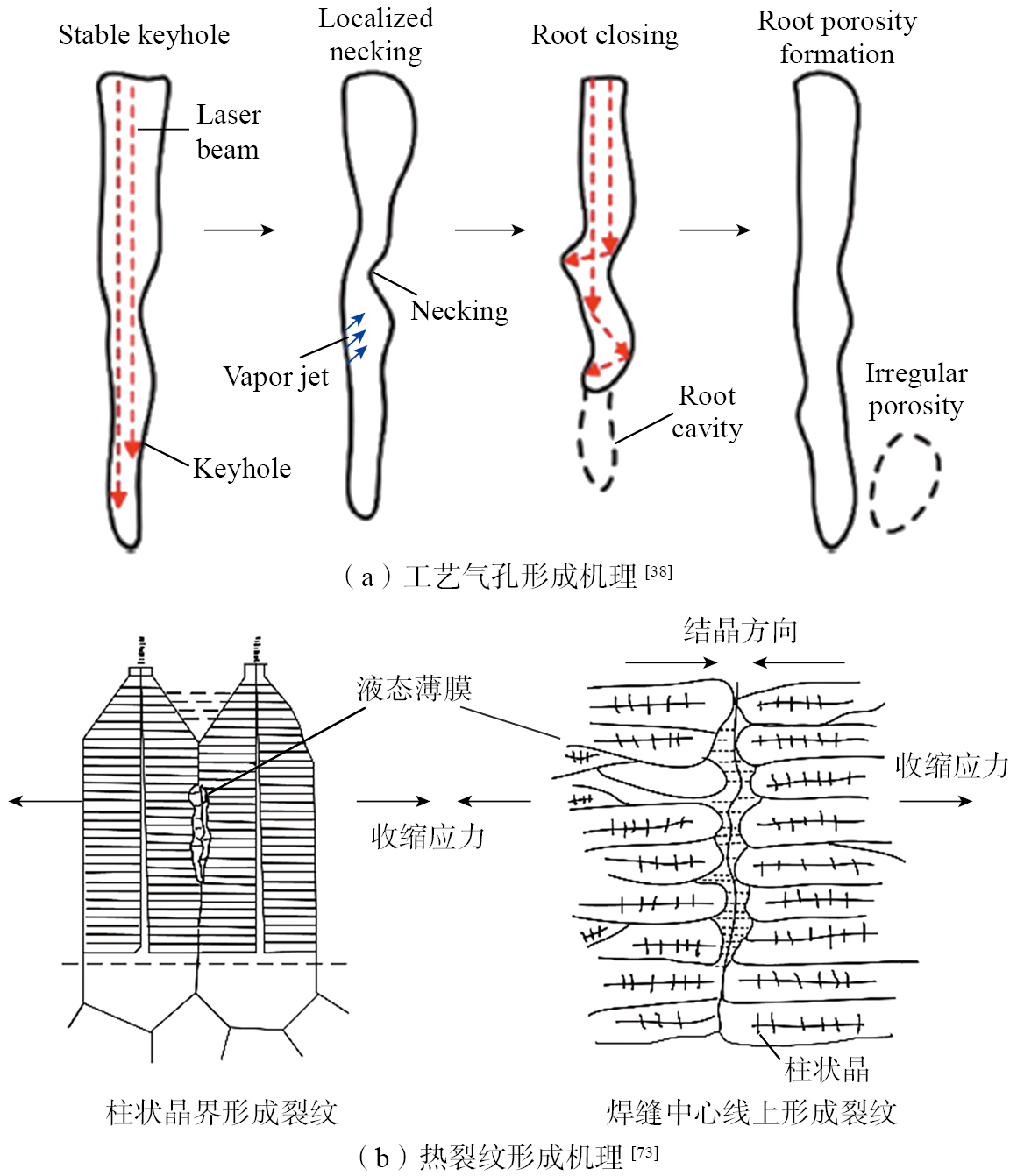

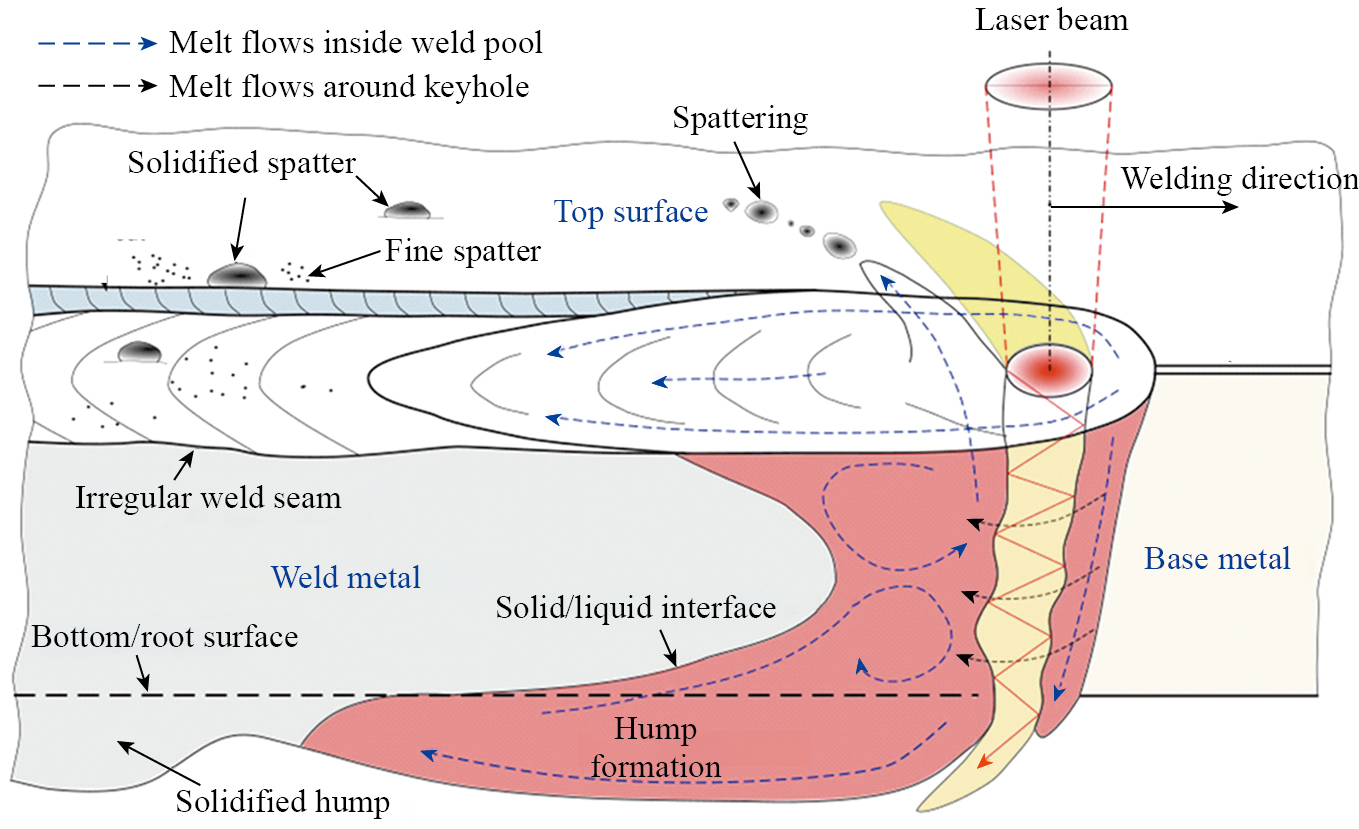

气孔一直是困扰铝合金熔化焊的问题。在传统焊接过程中,随着熔池温度降低,气体在熔池内的溶解度大幅度下降,由于液态金属的凝固速度较快,气体不能及时从焊缝中逸出,最终形成气孔。而在激光焊接过程中,由于金属蒸气导致的匙孔不稳定、熔池塌陷等,将进一步限制气体逸出[

38

39

40

41

42

43

27

铝合金具有较大的线膨胀系数和热膨胀系数,凝固时体积收缩率达6.5%~6.8%,因此焊接过程中熔融金属在凝固时会产生过大的收缩内应力,从而导致焊接变形。相比于电弧焊接,激光复合电弧焊接因焊接速度的提升与热输入的降低,使得焊缝的变形量明显小于电弧焊接[

44

45

46

47

23

激光功率与焦点位置是激光–电弧复合焊接中至关重要的参数,共同决定了焊接的质量和效率。激光功率决定了焊接过程中的热输入,当激光功率密度小于106 W/cm2时,为热导焊接模式;激光功率密度大于106 W/cm2时,为深熔焊接模式[

48

49

42

50

50

50

焦点位置则直接影响焊缝的几何尺寸与成形,当激光束的焦点位于工件表面以下时,通常可以得到最大的熔深[

51

52

53

根据电弧的动态特性可知,在焊接过程中其电流和电压是不断变化的。电流越大,焊条、焊丝等填充金属的熔化速率越快,热输入越高;电压越大,电弧长度越长[

54

55

56

对于复杂结构工件,改变焊接位置会导致焊接角度β的变化,使得焊缝池的重力方向与工件法线不重合,从而影响锁孔稳定性和焊缝液态金属流动[

57

58

当焊接间隙增大时,通常需要更高的送丝速度,意味着需要更大的焊接电流来提高沉积速率[

59

60

由于存在温度梯度,焊接接头热影响区的显微组织与性能不均匀,是焊接接头的薄弱位置,往往最先开始断裂。热影响区显微组织的晶粒形态一般可分为柱状晶、等轴晶与等轴枝晶,晶粒形态与所受热输入有关,而热影响区的力学性能通常与晶粒形态有关。表1[

YAN J, GAO M, LI G, et al. Microstructure and mechanical properties of laser–MIG hybrid welding of 1420 Al–Li alloy[J]. The International Journal of Advanced Manufacturing Technology, 2013, 66(9): 1467-1473.

ZHANG D Q, JIN X, GAO L X, et al. Effect of laser–arc hybrid welding on fracture and corrosion behaviour of AA6061–T6 alloy[J]. Materials Science and Engineering: A, 2011, 528(6): 2748-2754.

YANG M, LU J X, WANG H Y, et al. Effect of the laser power on the microstructure and mechanical properties of the laser–MIG hybrid welding joints of the 2195 Al–Li alloy[J]. Science and Technology of Welding and Joining, 2020, 26: 75-83.

HUANG L J, WU D S, HUA X M, et al. Effect of the welding direction on the microstructural characterization in fiber laser–GMAW hybrid welding of 5083 aluminum alloy[J]. Journal of Manufacturing Processes, 2018, 31: 514-522.

GU J X, YANG S L, XIONG Q, et al. Microstructure and mechanical study on laser–arc-welded Al–Zn–Mg alloy[J]. Materials Transactions, 2020, 61(1): 119-126.

ZHOU G A, XU J F, SHEN Z W, et al. Microstructure and mechanical properties of simultaneously explosively-welded steel/Cu pipes and Al/Cu pipe/rod[J]. Journal of Manufacturing Processes, 2019, 47: 244-253.

61-67

| 铝合金牌号 | 热影响区宽度/mm | 晶粒形态 | 文献 |

|---|---|---|---|

| AA5A06 | 0.5 | 等轴枝晶 | [ 61 |

| AA1420 | 1.0 | 等轴枝晶 | [ 62 |

| AA6061 | 1.0 | 等轴枝晶 | [ 63 |

| AA2195 | 5.0 | 等轴枝晶 | [ 64 |

| AA5083 | 6.0 | 柱状晶 | [ 65 |

| AA7075 | 7.0 | 柱状晶 | [ 66 |

| AA6N01 | 20.0 | 纤维状晶粒 | [ 67 |

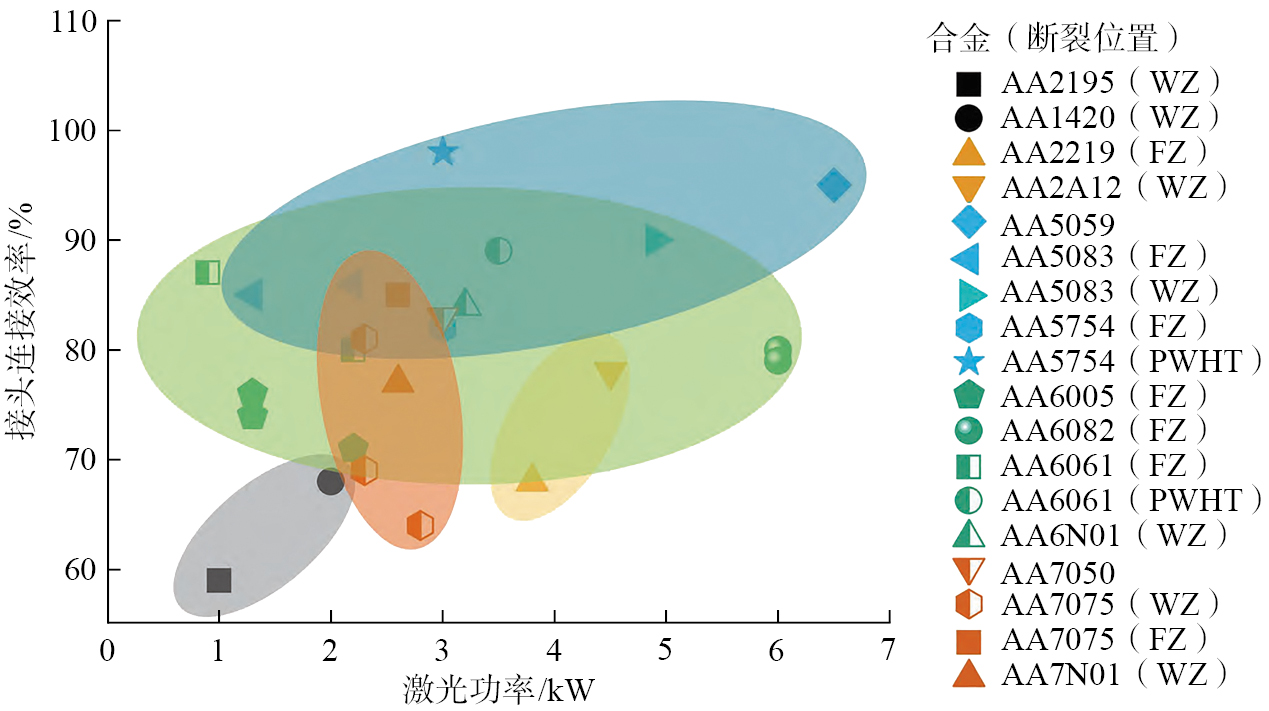

激光–电弧复合热源一方面能改善焊缝成形,减少气孔、热裂纹等缺陷;另一方面能控制热输入,减小热影响区尺寸,以此提高焊缝的综合力学性能。但接头软化仍是影响其力学性能的主要原因,目前主要通过两种方法来缓解接头软化的影响:(1)通过焊后热处理使接头产生固溶强化或第二相强化,如Hu等[

68

69

23

70

在实际工程应用中材料的疲劳性能十分重要,铝合金接头中气孔、裂纹均会引起应力集中,从而导致材料的疲劳性能下降。Wu等[

71

72

激光–电弧复合焊接接头中的常见缺陷包括气孔、热裂纹等,其中气孔主要分为氢气孔和工艺气孔两种。在较高的焊接温度下,铝合金熔池对氢气的溶解度较高,随着熔池的冷却,氢气溶解度急剧下降,较快的凝固速度使氢气无法完全逸出,最终形成氢气孔[

12

46

50

38

40

42

38

73

如图6所示[

13

13

74

75

13

13

根据目前铝合金复合焊接的相关研究可知,对于改善焊接接头成形、预防焊接缺陷产生,优化工艺参数是最简单、最有效的方法。马明明等[

76

77

78

BACHMANN M, AVILOV V, GUMENYUK A, et al. Experimental and numerical investigation of an electromagnetic weld pool control for laser beam welding[J]. Physics Procedia, 2014, 56: 515-524.

XU L D, TANG X H, ZHANG R L, et al. Weld bead characteristics for full-penetration laser welding of aluminum alloy under electromagnetic field support[J]. Journal of Materials Processing Technology, 2021, 288: 116896.

79-81

此外,保护气体种类及占比对焊缝成形也有重要影响。Cai等[

82

铝合金厚板焊接在船舶、火箭、军工领域的应用十分广泛。MIG焊接的熔透能力较弱,在厚板焊接中需要较大的坡口角度和较小的钝边高度,并且需要较多的焊接层道数,而多道MIG焊接过程中累积的焊接热输入大,导致焊接变形大、残余应力高、力学性能差,因此影响接头的使用寿命[

83

84

85

86

使用电弧焊对铝合金进行焊接时能得到成形良好的接头,但其熔透能力较弱,焊接时所需的热输入较高,导致焊件的焊接变形大,接头力学性能不稳定。而复合焊接之所以能够增大熔深,一方面是因为电弧能够预热铝合金表面,提高了激光的能量利用率,使得焊缝熔深增大[

87

88

89

66

29

90

91

在传统铝合金厚板焊接中,一般需要进行多层多道次焊接,难免造成较大的热输入,导致焊缝产生变形。而在复合焊接中,热输入显著降低,焊接接头的残余应力与变形量也随之下降。王良等[

92

93

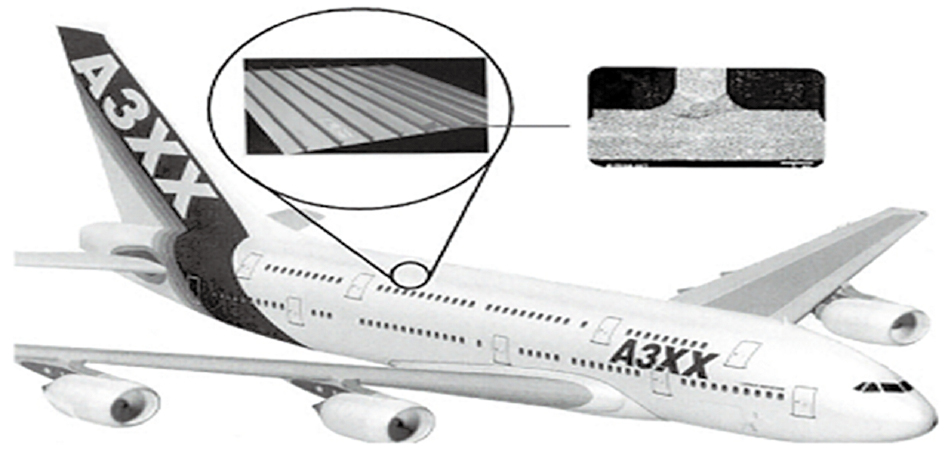

铝合金密度较低,经过热处理强化后,强度接近于低碳钢,因此被广泛应用于航空航天的结构轻量化设计中。减轻飞机重量不仅可以消耗更少的燃油,还能提高飞行速度、降低噪音和振动。同时,铝合金在制造过程中的可塑性和可加工性使得该材料能被制成复杂的形状和结构,进一步满足轻量化设计的需求[

94

95

96

97

95

95

| 铝合金牌号 | 主要特点 | 应用部位 | 主要状态 |

|---|---|---|---|

| 1420 | 密度小,耐腐蚀性好 | 机身蒙皮和纵梁、座舱、油箱、地板、翼肋 | — |

| 2024 | 强度高,综合性能较好 | 飞机蒙皮、骨架、肋梁、螺旋桨等 | T351、T4、T851 |

| 2324 | 高强度,高韧性 | 飞机结构件 | T39 |

| 3003 | 良好的耐腐蚀性和延展性 | 发动机过滤网 | H22 |

| 5052 | 中等强度,良好的耐腐蚀性和焊接性 | 风扇叶片、储油箱 | H32、H34、H112 |

| 7085 | 高强度,综合性能好 | 桁条 | T7651 |

| 7175 | 高强度,良好的耐腐蚀性和断裂韧性 | 飞机外翼梁、主起落架、垂尾接头 | T74、T7452、T76511 |

97

97

由于飞机在飞行过程中需要承受自身的重量和飞行过程中的各种载荷,因此对机身材料的抗拉强度和疲劳性能要求非常严格。Vaidya等[

98

99

100

101

100

100

近年来,伴随着激光器行业的高速发展与制造工业的技术迭代,铝合金激光–电弧复合焊接技术已经受到越来越多研究人员的关注。除航空航天外,激光–电弧复合焊接技术因其高效率、高质量的优势在其他工业领域(如汽车制造、船舶与电力等)中也得到了广泛应用,如表3所示[

94

STAUFER H. Laser hybrid welding in the automotive industry[J]. Welding Journal, 2007, 86(10): 36-40.

ROLAND F, REINERT T, PETHAN G. Laser welding in shipbuilding—An overview of the activities at Meyer Werft[J]. Welding Research Abroad, 2003(4): 49.

CHURIAQUE C, SÁNCHEZ-AMAYA J M, ÜSTÜNDAĞ Ö, et al. Improvements of hybrid laser arc welding for shipbuilding T-joints with 2F position of 8 mm thick steel[J]. Optics & Laser Technology, 2021, 143: 107284.

ADAMIEC J, WIĘCEK M, GAWRYSIUK W. Fibre laser usage in boiler elements’ production for the power industry[J]. Welding International, 2010, 24(11): 853-860.

102-106

| 应用企业 | 应用产品 | 优势 | 文献 |

|---|---|---|---|

| 德国大众 | Phaeton全铝车门 | 提升生产效率 | [ 102 |

| 德国大众 | 奥迪A8铝合金侧顶梁 | 提升角焊缝与对接焊缝质量 | [ 102 |

| Daimler | 车轴生产 | 提升效率、熔透性及冶金性能 | [ 103 |

| Fronius | 激光–CMT复合焊头 | 降低热输入,提升熔深 | [ 94 |

| Meyer–Werft GmbH | 船舶加强板 | 降低变形,提升生产率 | [ 104 |

| Fincantieri | 船舶甲板 | 降低变形,提升接头桥接能力 | [ 105 |

| Energoinstall | 锅炉墙板和加肋 | 接头间隙公差大、熔深大,生产率高 | [ 106 |

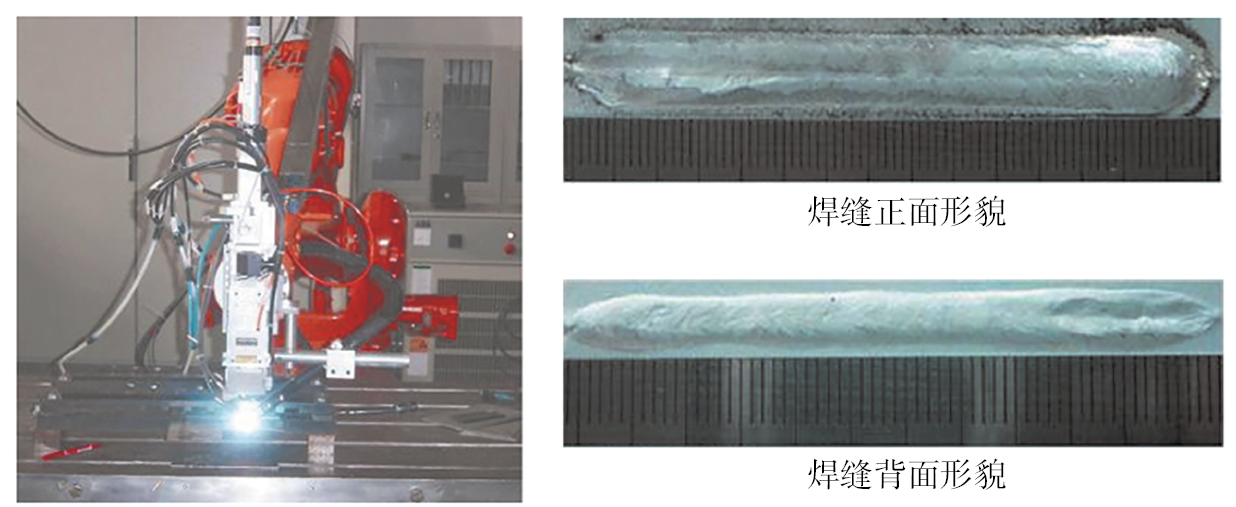

铝合金激光–电弧复合焊接自动化系统通常包括激光源、电弧源、焊接机器人、送丝系统、控制系统等关键组件,这些组件的协同工作可以实现焊接过程的自动化控制。激光–电弧复合焊自动化与智能化焊接技术的发展,是推动制造业迈向更高效、更精准、更可靠生产模式的关键。早在2000年,Fraunhofer ILT在一家油箱制造公司搭建了激光–电弧复合焊接的自动化系统[

107

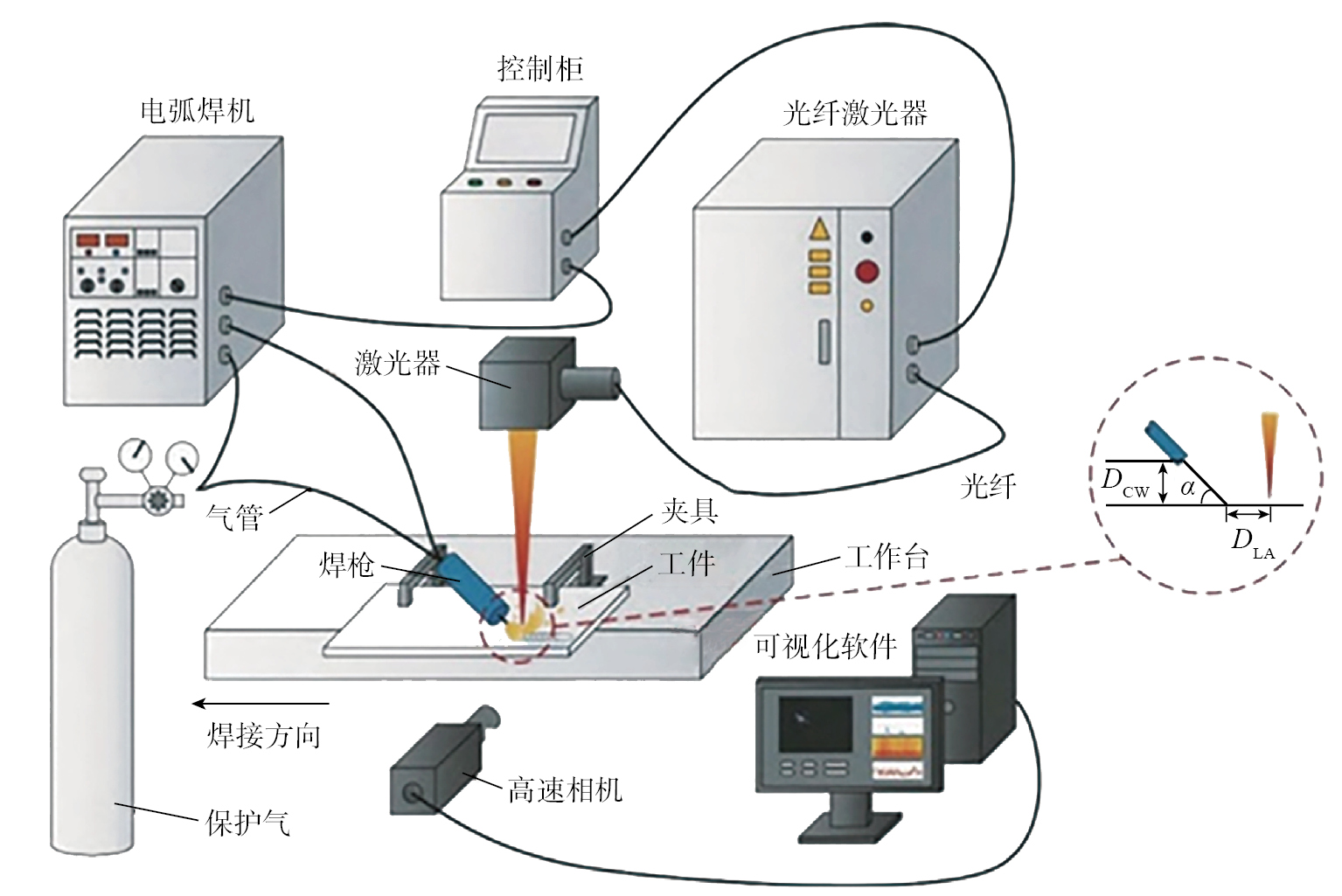

如图9所示[

50

50

108

109

110

50

50

保护气体能够有效隔绝空气中对焊缝有害的气体,防止这些气体与熔池中的液态金属发生反应,以免导致焊缝中产生气孔、热裂纹等缺陷,从而影响焊接质量。然而,保护气体的成分会影响电弧特性、焊缝轮廓的形成和熔滴过渡行为[

111

112

82

113

114

填充材料用于调控焊缝金属的化学成分,以减少热裂纹等缺陷并提高接头整体的力学性能。通常,填充焊丝5356、5556、5183适用于大多数铝合金[

13

23

115

116

近年来,随着铝合金激光–电弧复合焊接技术的日渐成熟,已有研究人员将该技术应用于铝合金的增材制造中。王鹏[

117

118

119

120

对于铝合金来说,焊后热处理对接头质量有较大提升,可热处理的铝合金有2系、6系及7系。刘晓红等[

121

122

(1)激光–电弧复合焊接将激光焊接和电弧焊接两种热源的优势融合到一起,所得焊缝既有较大的熔深,又能保持较小的变形,通过优化工艺参数可使铝合金复合焊接接头的性能得到进一步提升。

(2)针对热影响区软化、焊缝内部缺陷(热裂纹、气孔)与外部缺陷(驼峰、飞溅)等问题,可通过优化工艺参数、添加合金成分及焊后热处理等方法进行解决。针对铝合金厚板焊接,激光–电弧复合焊接较高的电弧熔透能力及协同作用能够降低接头的变形和残余应力。

(3)铝合金激光–电弧复合焊接技术在交通运输、船舶制造、电力工程等领域已有相对成熟的应用,在航空航天领域已经开展大量试验探索,具有很大的发展潜力。

(4)将激光–电弧复合焊接技术与增材制造技术相结合,能够显著改善增材构件的成形性及机械性能。对复合焊接接头进行热处理可改善接头软化、力学性能不足等问题。

(5)随着科技的进步,未来铝合金激光–电弧复合焊接技术将朝着智能化与自动化方向发展,通过对焊接过程进行实时监控与反馈控制,可以对焊接质量进行有效评估,是复合焊接技术走向智能化的重要一步,实现复合焊接技术的自动化将有助于该技术在工业领域的进一步应用。

| 陈超 研究员,研究方向为智能与精密焊接/增材制造。 |

参考文献

| [1] | |

| [2] | |

| [3] | |

| [4] | |

| [5] | |

| [6] | |

| [7] | |

| [8] | |

| [9] | |

| [10] | |

| [11] | |

| [12] | |

| [13] | |

| [14] | |

| [15] | |

| [16] | |

| [17] | |

| [18] | |

| [19] | |

| [20] | |

| [21] | |

| [22] | |

| [23] | |

| [24] | |

| [25] | |

| [26] | |

| [27] | |

| [28] | |

| [29] | |

| [30] | |

| [31] | |

| [32] | |

| [33] | |

| [34] | |

| [35] | |

| [36] | |

| [37] | |

| [38] | |

| [39] | |

| [40] | |

| [41] | |

| [42] | |

| [43] | |

| [44] | |

| [45] | |

| [46] | |

| [47] | |

| [48] | |

| [49] | |

| [50] | |

| [51] | |

| [52] | |

| [53] | |

| [54] | |

| [55] | |

| [56] | |

| [57] | |

| [58] | |

| [59] | |

| [60] | |

| [61] | |

| [62] | |

| [63] | |

| [64] | |

| [65] | |

| [66] | |

| [67] | |

| [68] | |

| [69] | |

| [70] | |

| [71] | |

| [72] | |

| [73] | |

| [74] | |

| [75] | |

| [76] | |

| [77] | |

| [78] | |

| [79] | |

| [80] | |

| [81] | |

| [82] | |

| [83] | |

| [84] | |

| [85] | |

| [86] | |

| [87] | |

| [88] | |

| [89] | |

| [90] | |

| [91] | |

| [92] | |

| [93] | |

| [94] | |

| [95] | |

| [96] | |

| [97] | |

| [98] | |

| [99] | |

| [100] | |

| [101] | |

| [102] | |

| [103] | |

| [104] | |

| [105] | |

| [106] | |

| [107] | |

| [108] | |

| [109] | |

| [110] | |

| [111] | |

| [112] | |

| [113] | |

| [114] | |

| [115] | |

| [116] | |

| [117] | |

| [118] | |

| [119] | |

| [120] | |

| [121] | |

| [122] | |